Ask the Experts

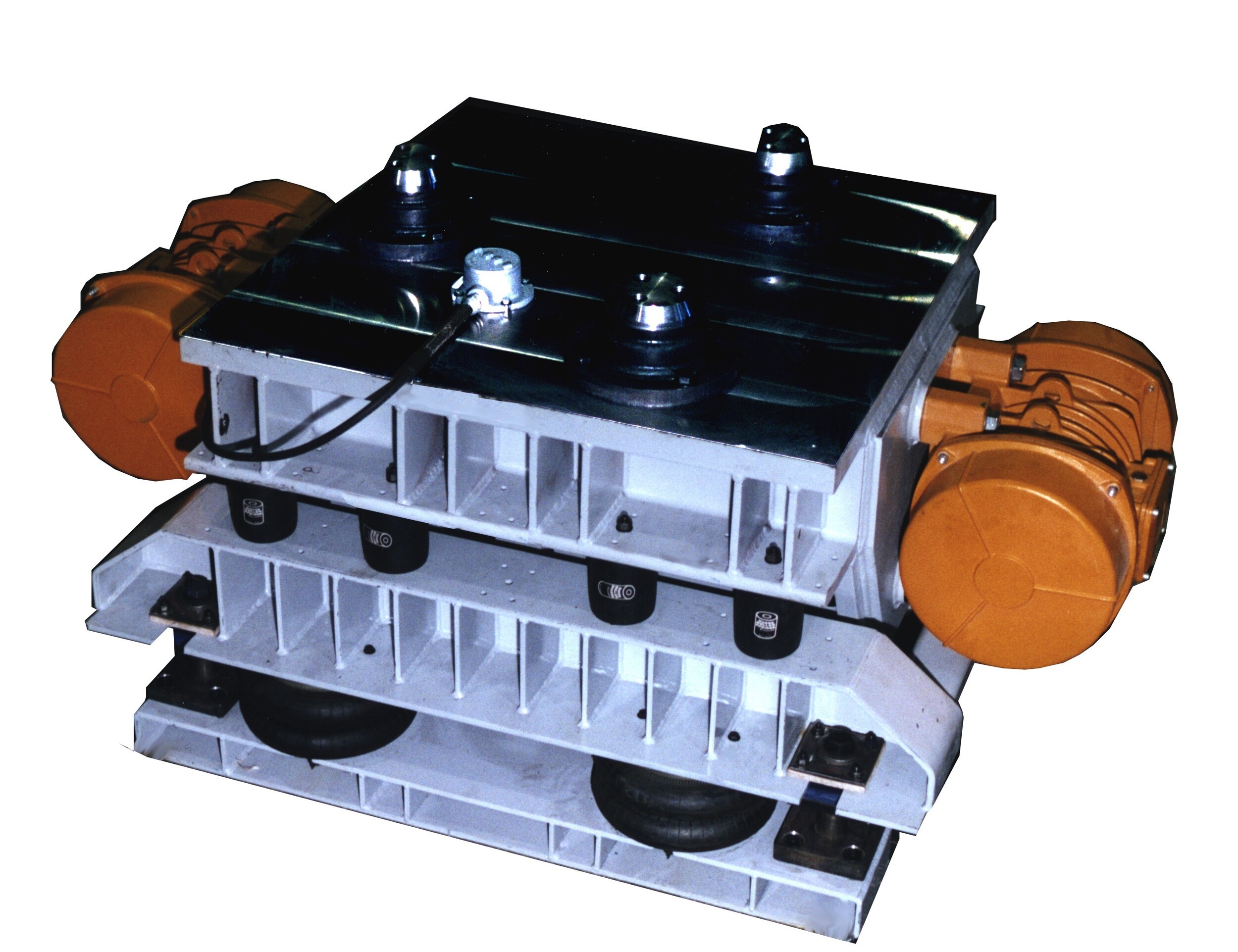

Compaction Tables

Lost foam and no bake molding techniques demand superior mold compaction in order to develop casting integrity and maintain profitable production.

General Kinematics compaction tables fluidize sand to obtain optimum sand migration around all pattern surfaces, an important advantage in polystyrene processes involving intricate shapes.

Sand is compacted to maximum density and hardness, producing close tolerance castings with good surface finish. Quality is improved, with less scrap and lower unit costs.

Flask clamping eliminated

The stable, three-point flask support has unique, contoured, sound deadening flask fixtures which precisely locate and secure flask during compaction cycle. Separate clamping devices are eliminated, speeding production and eliminating maintenance.

Programmed operation

Computerized, variable control is programmed for the vibratory action needed for each specific pattern. As flask fills, integrated feedback automatically compensates for increasing sand weight to sustain desired vibration intensity.

Features:

- The stable, three-point flask support has unique, contoured, sound deadening flask fixtures which precisely locate and secure flask during compaction cycle. Separate clamping devices are eliminated, speeding production and eliminating maintenance.