Ask the Experts

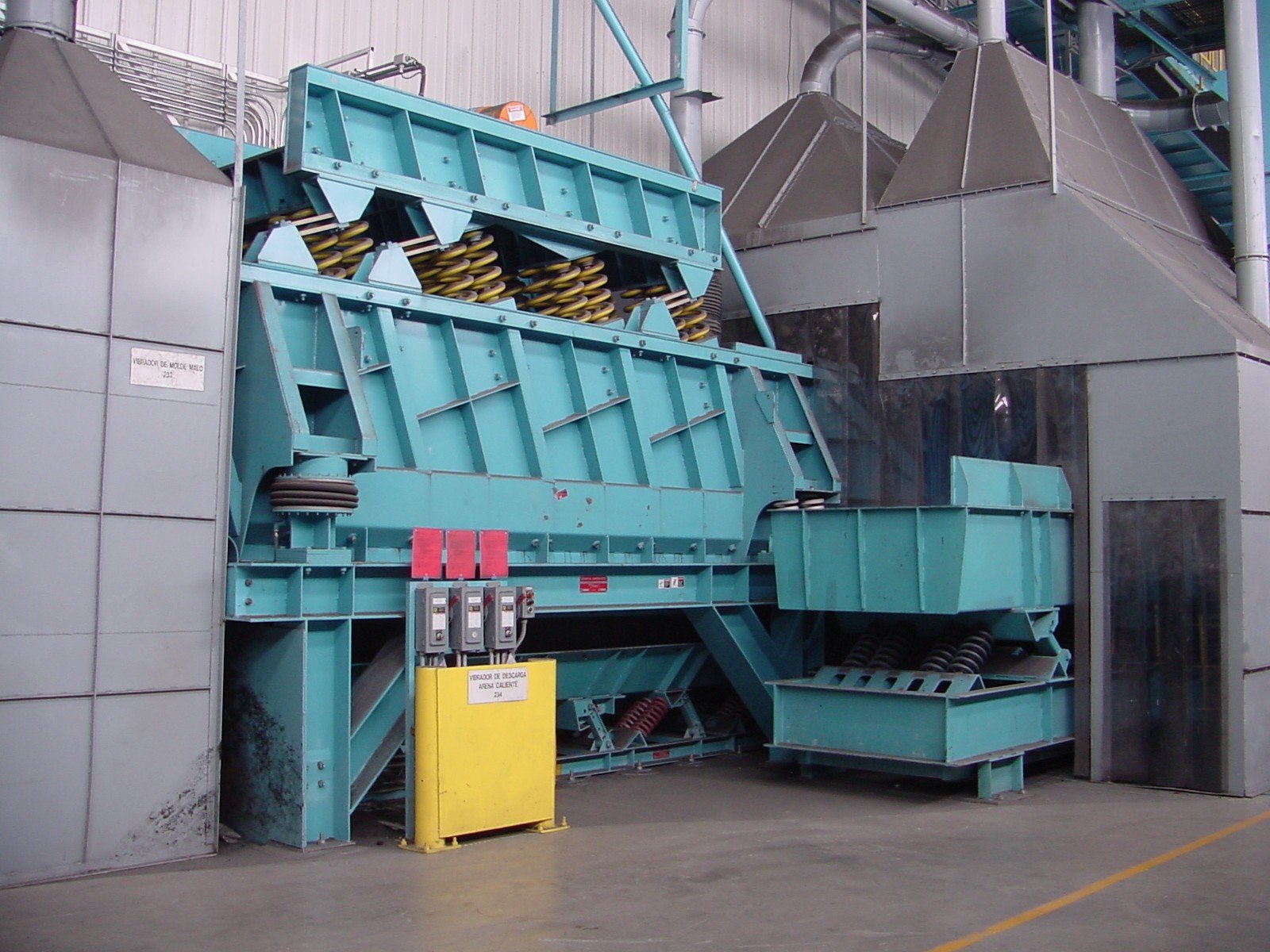

Two-Mass Conveying Shakeout

General Kinematics’ high frequency, Two-Mass Shakeouts will boost your foundry throughput. Our unique Two-Mass design automatically compensates for varying load conditions, assuring non-dampening shakeout performance.

General Kinematics Shakeouts are specifically designed for your high production molding lines. Capacities range from 30 to 300 tons per hour for gray, ductile or malleable iron. Each shakeout is sized to maintain the proper casting retention time to break down your sand while preventing excessive casting batter.

Two-Mass technology allows the use of variable frequency drives to vary the amount of G-Force applied to break down the sand. General Kinematics’ specially designed isolation system allows for incline or decline of the shakeout surface thereby maintaining castings in the shakeout for the desired retention time based on your part number.

Features:

- The unique GK Two-Mass design automatically compensates for varying load conditions, assuring non-dampening shakeout performance.

- Driven with proprietary sealed vibration shaker motors, GK’s Two-Mass Shakeouts eliminate the need for V-belts, pivoted motor bases, couplings, and large and expensive bearings.

- The drive for our shakeout feeders is mounted on a separate exciter mass, completely isolated from the high-intensity impact action of the shakeout deck.

- Our vibration shaker units feature low horsepower, adjustable amplitude control, and exceptionally quiet operation.