Ask the Experts

VIBRA-MILL® Vibratory Batch Sand Reclamation

Shakes, agitates, vibrates, tumbles, and abrades up to 4 foot lumps to minus 20 mesh grain size. Automatically.

The VIBRA-MILL® Vibratory Batch Sand Reclamation has proven itself in scores of foundries as both a total attrition mill and as a sand preconditioner. It often eliminates the need for larger, more costly equipment and systems while actually improving production rates. Also, the VIBRA-MILL® sand reclamation efficiency greatly reduces the purchase of new sand.

Construction

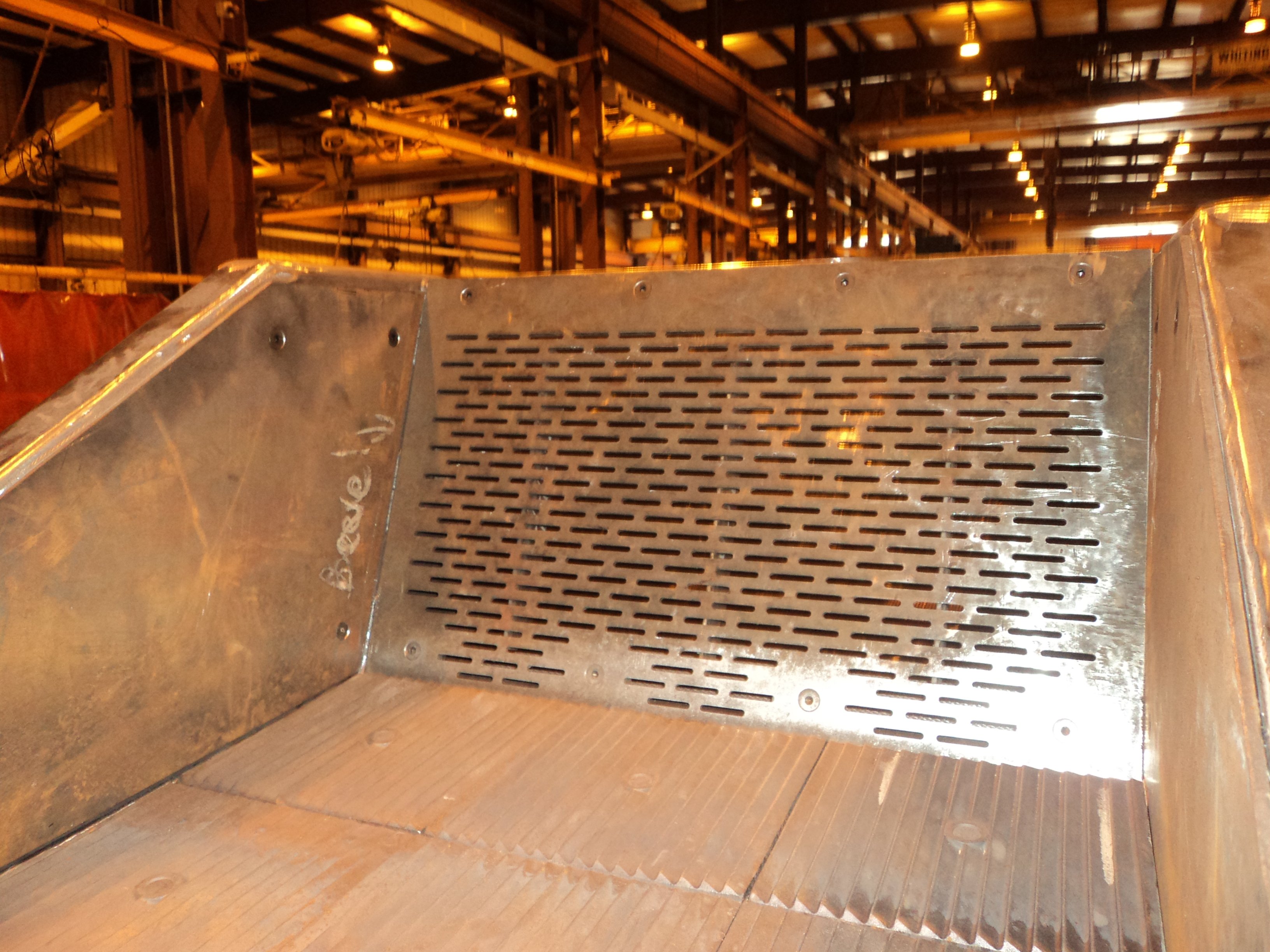

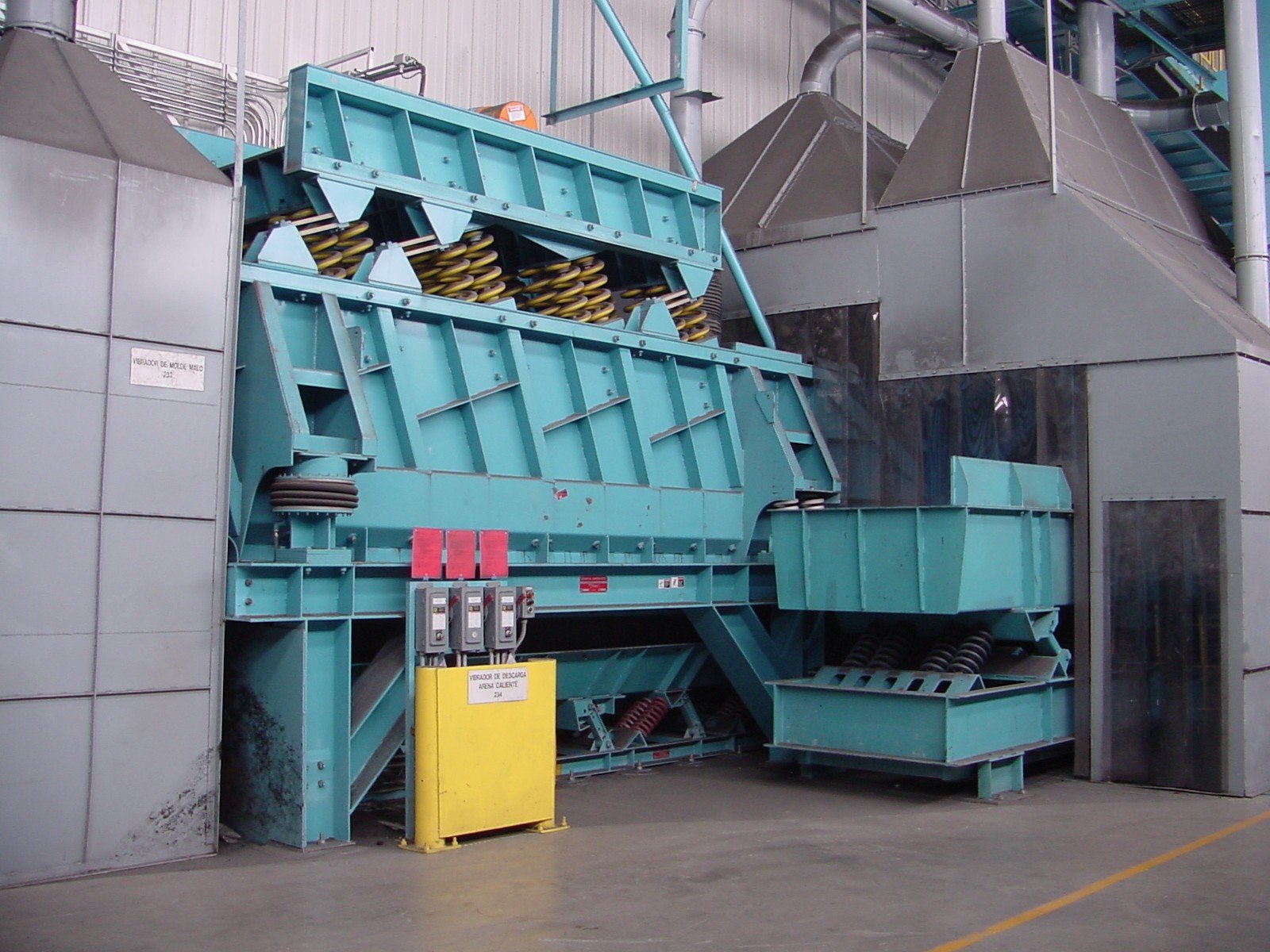

Mounted on low-stress steel coil isolation springs to minimize floor vibration, VIBRA-MILL® features an open tub design that eliminates maintenance and operational problems inherent in multiple deck units. With GK’s standard VIBRA-MILL® design, manual clean-out of the tub is unnecessary. GK now offers optional enclosed VIBRA-MILL designs to reduce dust and airborne silica.

Compact in design, the largest VIBRA-MILL® model occupies just under 81 square feet of floor space. It can easily be incorporated into most existing systems for improved production and savings.

Capacity

Production rates of up to fifty+ tons per hour can be sustained while reducing a normal mixture of lumps and sand to original grain size.

Final Grain Size

Lumps are reduced to minus 20 mesh with original grain size distribution and corresponding reduction in L.O.I. With proper addition of new sand, reclaimed material is clean and ready for new mold production without further attrition.

Separation Capability

To assure clean sand, tramp material such as metallics, ceramics, core wires, etc. are conveyed and unloaded through an air operated gate at one end of the unit.

At the opposite end, fine sand passes through an air sweep exhaust where fine organics are removed; then also over a final sizing screen for separation of ceramic and metallic particles.

Low Noise Level

Quiet, smooth operating VIBRA-MILL® conforms to the most stringent industry noise specifications.

Drive System

Drive system is a tandem unit of self-contained motorized drives from 2 to 7 ½ hp. each, depending on the VIBRA-MILL® model. They create the vibrating action necessary to process sand lumps into original grain size. Motors are specially constructed for vibratory service, and feature dust-tight, totally enclosed design. Drives are easily accessible for service and maintenance.

On standard VIBRA-MILL® models, a third drive is used during the trash unloading cycle to produce a reverse conveying action and to clear the primary screen. For High-Energy VIBRA-MILL® designs, clean out must be completed manually.

Motor dependability, simplified drive, and easy accessibility contribute to the trouble-free performance of VIBRA-MILL® equipment.

Not Just For Sand

VIBRA-MILL® is a truly versatile piece of equipment. In fact, there are many industries where VIBRA-MILL® tumbling and attrition action can be added to the processing cycle, to speed up production and save costs. For example, the scrap metal industry uses VIBRA-MILL® to process metal pieces before briquetting. Foundries also use VIBRA-MILL® for recovery of non-ferrous materials, like aluminum, bronze, brass, and special alloys.

Contact your General Kinematics representative about how GK’s VIBRA-MILL® can help your operation achieve greater production savings.

Features:

- Special vibratory service motors for increased uptime.

- Various feed options depending on application.

- High capacity reclamation rates.

- Simple, open tub design for easy loading.

- Optional totally enclosed designs available.

- Single jam-proof deck.

- Provides fines removal.