GENERAL

KINEMATICS

FOUNDRY

EQUIPMENT

SPOTLIGHT

Learn more

General Kinematics is a world leader of innovation and production for Foundry and metalcasting systems and equipment. Top foundries around the world have trusted GK to improve their systems. Explore the GK Foundry Equipment Universe below. Hear from North American Foundry Director, Rick Kempf, read case studies, watch videos, and more.

North American Foundry Director | Rick Kempf

Rick started at General Kinematics in 1994 as a design engineer, later moving to the sales department and becoming North American Sales Manager. Rick holds five patents from his time with General Kinematics including a patent he shares with General Kinematics’ President, Tom Musschoot. Rick was appointed to lead General Kinematics North America Foundry Department in 2019 due to his extensive technical knowledge of foundry equipment and experience in all departments of the foundry.

Have a question about GK Foundry Equipment? Ask Rick!

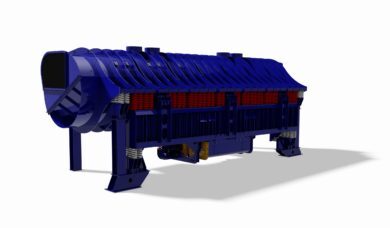

VIBRA-DRUM® Sand & Casting Conditioner

Discover the benefits of General Kinematics’ 3-in-1 foundry solution.