Ask the Experts

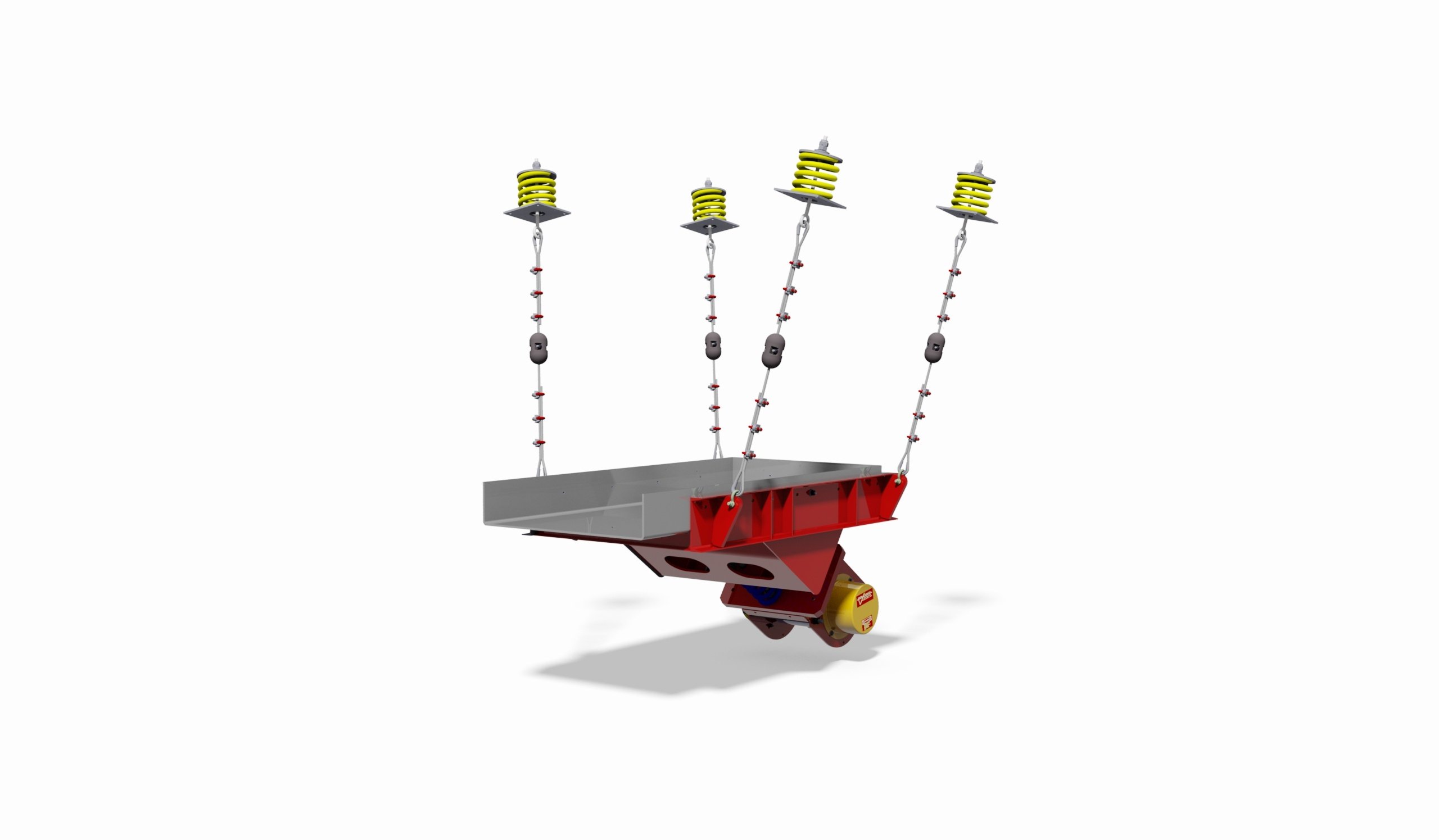

UN-COALER® Bin Activator / Feeder

Feeding & Activation in a single, low-profile machine

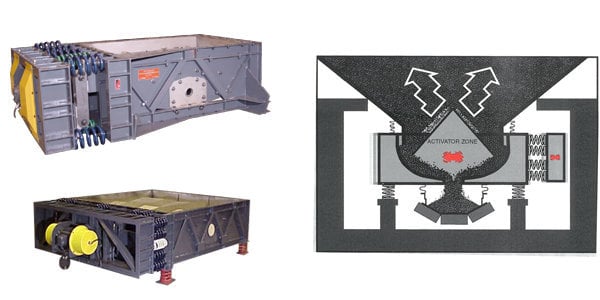

The UN-COALER® Activator/Feeder is a state-of-the-art solution that combines the flow control characteristics of an enclosed vibrating feeder with proven bin activation in a single, compact, high-performance vibratory unit.

Since the unit discharges coal vertically to the conveyor below, loading is always centered and symmetrical. This feature helps eliminate belt tracking problems that are common to side feeding. The UN-COALER® also helps eliminate bridging and other issues found with other metering options. The unique center dome design works as a pile activator or vibratory hopper bottom to help move difficult mined materials and eliminate bridging.

Significantly reducing tunnel width and height requirements, the UN-COALER® provides considerable cost savings during construction, while maintaining easy access for inspection and maintenance. Engineered for your application, we can customize the VIBRA-FLOW™ to fit your footprint.

Benefits

- Unique center dome design works as a pile activator or vibratory hopper bottom to help move coal and eliminate bridging.

- Compact, low equipment profile reduces civil work, foundation costs, fits in tight spaces, and simplifies installation.

- Versatile design adapts to reclaim in windrows, storage barns, silos, trucks, or rail hoppers.

- Two-Mass drive design operates under full load conditions with ease.

- Drive is located outside of material flow for easier maintenance.

- Simplified hopper design with easy, straight-line dust sealing.

- No gates required.

- Symmetrical and centered loading.

Below are a few typical applications of General Kinematics UN-COALER®.

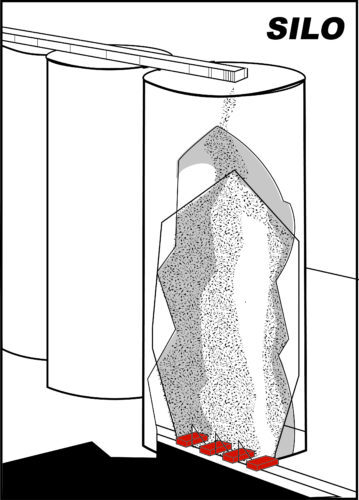

Where the 100% reclaim advantages of silo storage are employed, the UN-COALER® provides a cost-efficient and high-tonnage activating / feeder function. For example, a 70-foot diameter silo can be reclaimed with only four UN-COALER® units installed in line directly over the belt, providing rates up to 8000 TPH.

Mass flow design, coupled with high reliability and low installed cost, makes the UN-COALER® uniquely suitable for silo storage systems. Along with measurable performance advantages, the UN-COALER® also reduces operators’ expenses in operating and maintenance.

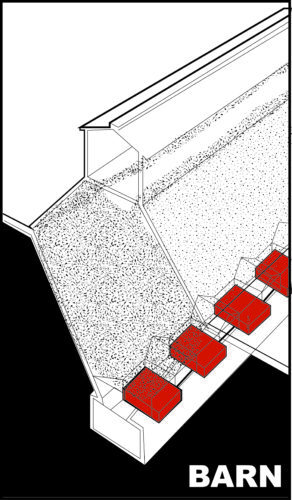

This 100% live reclaim facility maximizes the cost and operating advantages of UN-COALER® design. An entirely enclosed structure, the barn-type storage unit has sloping sides running the length of the building. A series of UN-COALER® units are located in the reclaim tunnel at the base, sized with up to 12 by 12-foot openings and spaced along the tunnel to produce the desired reclaim volume. Any percentage of material can be reclaimed simultaneously from any part of the pile.

In this and other tunnel applications with multiple units, the operator may include fixed and variable feed rates on the UN-COALER® to properly control blending and feed rate. Particularly in barn storage situations, the UN-COALER® units’ low headroom and total access from the tunnel facilitate structural and service efficiency. And for extremely long conveyor runs, the perfectly centered loading pattern virtually eliminates belt tracking problems associated with multiple discharge feeder systems.

Because the UN-COALER® is supported from the floor, structural considerations and suspended equipment costs are eliminated.

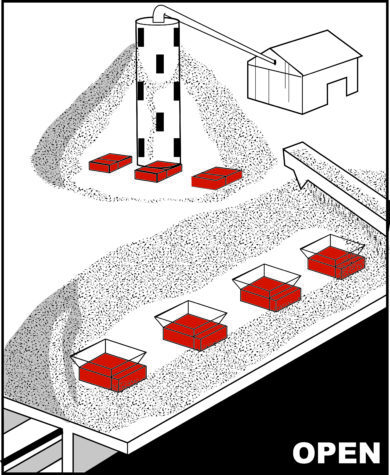

The convenience and cost savings of open storage systems, either conical pile or windrow, are enhanced further by the unique installation advantages of the UN-COALER®. Lower headroom design and entirely free-standing floor mounting significantly reduce construction costs, concrete work, and tunnel depth. UN-COALER®’s straight line effective dust sealing, plus the option of explosion-proof motors and controls, minimizes dust hazards.

The windrow schematic illustrates the live reclaim efficiency of UN-COALER® installations. Eliminating rat-holing, bridging, and intersecting reclaim patterns assures maximum drawdown and reclaim rates with less equipment expense.

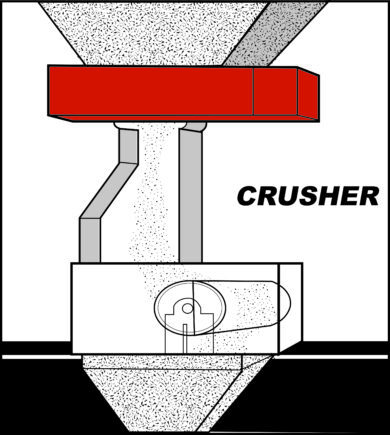

Mounted directly above a crusher, the UN-COALER® units ‘low profile and straight-line design greatly simplify hopper and dust seal installation. With 100% linear feed rate adjustment, the UN-COALER® provides a constantly uniform discharge into the crusher, assuring maximum efficiency and extended wear life on the crusher elements.

A long, narrow discharge slot is ideal for even material distribution across the crusher inlet, again without expensive transition pieces or added height requirements. The gravity flow in-line concept reduces the crusher house size.

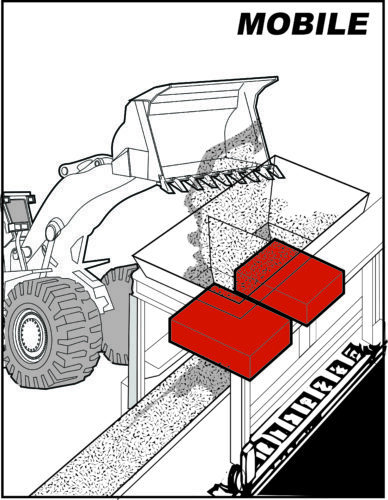

As an alternative to more costly bucket reclaimers, the mobile rail-mounted UN-COALER® produces high volume results with less equipment investment. Here, a wheeled or track-mounted loader scoops material into tandem UN-COALER® units mounted on a rail vehicle. The loader and UN-COALER® move along the full windrow length, working as a high-volume reclaim system. A fixed conveyor is located between the rails where direct vertical discharge from the UN-COALER® produces even feed rates and belt loading.

The economy and reliability of this system, which permits coal handling at less cost per ton, is made possible only by the unique structural and operating advantages of the UN-COALER® unit.

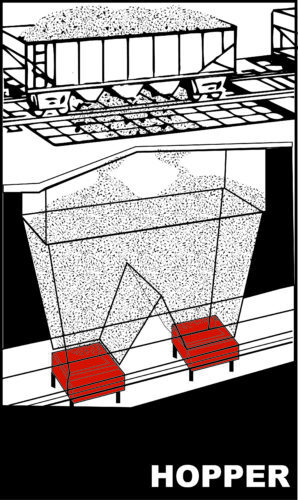

As unit trains or dump trucks deposit enormous quantities of material into large hoppers, the UN-COALER® provides the capacity and feed rate control necessary to distribute it efficiently. The large rectangular opening of the UN-COALER® mounted directly over the conveyor assures maximum drawdown.

The UN-COALER® is equipped with infinitely variable drive systems, permitting direct response to computer load cell or belt scale signals, affording automatic and exact proportioning or blending.

UN-COALER® MAP

Case Studies

Size Chart

Standard Sizes & Capacities

| DIMENSIONS | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model # | HP | A | B | C | D | E | F* | G | H | J | K | L | M* | N |

| UC 4 x 4 | 3 | 2′ 0″ | 2′ 6″ | 4′ 4″ | 2′ 3″ | 2′ 1″ | 10′ 7″ | 3′ 1″ | 2′ 0″ | 1′ 8″ | 1′ 11″ | 1 1/2″ | 10′ 7″ | 4″ |

| UC 5 x 5 | 3 | 2′ 6″ | 3′ 0″ | 5′ 11″ | 2′ 9″ | 3′ 2″ | 12′ 8″ | 3′ 1″ | 2′ 6″ | 2′ 0″ | 2′ 6″ | 3″ | 11′ 2″ | 5″ |

| UC 6 x 6 | 5 | 3′ 0″ | 3′ 8″ | 6′ 7″ | 3′ 4″ | 3′ 3″ | 13′ 11″ | 3′ 7″ | 3′ 0″ | 2′ 4″ | 2′ 9″ | 2 1/2″ | 11′ 5″ | 7″ |

| UC 7 x 7 | 5 | 3′ 6″ | 4′ 2″ | 7′ 1″ | 3′ 10″ | 3′ 3″ | 14′ 11″ | 4′ 1″ | 3′ 6″ | 2′ 8″ | 3′ 1″ | 2 1/2″ | 11′ 9″ | 8″ |

| UC 8 x 8 | 10 | 4′ 0″ | 4′ 10″ | 8′ 1″ | 4′ 5″ | 3′ 8″ | 16′ 6″ | 4′ 7″ | 4′ 0″ | 3′ 0″ | 3′ 5″ | 2 1/2″ | 12′ 1″ | 9″ |

| UC 9 x 9 | 10 | 4′ 6″ | 5′ 4″ | 8′ 7″ | 4′ 11″ | 3′ 8″ | 17′ 6″ | 5′ 1″ | 4′ 6″ | 3′ 0″ | 3′ 5″ | 2 1/2″ | 12′ 1″ | 10″ |

| UC 10 x 10 | 15 | 5′ 0″ | 5′ 10″ | 11′ 0″ | 5′ 5″ | 5′ 7″ | 20′ 5″ | 5′ 7″ | 5′ 0″ | 3′ 8″ | 4′ 1″ | 2 1/2″ | 12′ 9″ | 10″ |

| UC 11 x 11 | 15 | 5′ 6″ | 6′ 4″ | 11′ 6″ | 5′ 11″ | 5′ 7″ | 21′ 5″ | 6′ 1″ | 5′ 6″ | 3′ 8″ | 4′ 1″ | 2 1/2″ | 12′ 9″ | 11″ |

| UC 12 x 12 | 15 | 6′ 0″ | 6′ 10″ | 12′ 0″ | 6′ 5″ | 5′ 7″ | 22′ 5″ | 6′ 7″ | 6′ 0″ | 3′ 8″ | 4′ 1″ | 2 1/2″ | 12′ 9″ | 10″ |

| * Typical Dimension Varies with Installation. For installation, request certified dimensions. | ||||||||||||||

| CAPACITIES | |||

|---|---|---|---|

| Model # | Capacity | Max Lump | Ship WT (lbs) |

| UC 4 x 4 | 120 | 5″ | 3000 |

| UC 5 x 5 | 225 | 6″ | 3500 |

| UC 6 x 6 | 400 | 8″ | 6000 |

| UC 7 x 7 | 550 | 9″ | 9000 |

| UC 8 x 8 | 700 | 10″ | 12000 |

| UC 9 x 9 | 1000 | 11″ | 15000 |

| UC 10 x 10 | 1300 | 12″ | 17000 |

| UC 11 x 11 | 1700 | 14″ | 19000 |

| UC 12 x 12 | 2000 | 15″ | 22000 |

| Capacity in tons per hour based upon bulk material such as coal, weighing 50 lbs. per cu. ft. | |||