For more than 80 years, Kirsh Foundry has built its reputation on quality castings and a commitment to continuous improvement. When manual casting handling began limiting productivity, the Kirsh team turned to General Kinematics to find a better way. In this video case study, see how GK engineered a cooling system to fit the foundry’s tight footprint, automate material flow, and transform a once-manual process into a faster, safer, and more efficient operation that now moves castings from molding to finishing in just one day.

GK Customer Success Story- Kirsh Foundry

Read the full case study here!

“It’s the smoothest that it’s been in my lifetime here. We look for three things: safety gains, productivity gains, or environmental gains. And this project satisfied all three.”

– Jim Kirsh, CEO of Kirsh Foundry.

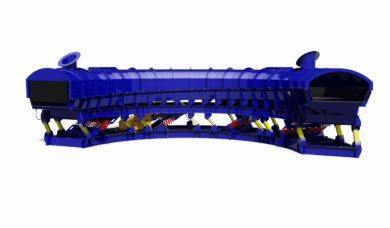

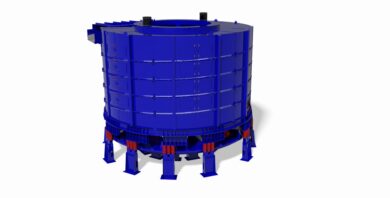

CASTING COOLING EQUIPMENT

Contact Us

Explore GK Foundry

For more information on GK Foundry products and systems, visit: