The State of Aggregate Screening

Aggregate screens are the heart of aggregate processing sites. If they’re not properly separating materials, you’re missing out on valuable revenue. Here’s a little bit of insight on GK’s process when it comes to optimizing equipment for customer aggregate sites, and a few predictions on the future of the industry.

How Does GK Choose the Right Aggregate Screen for Your Application?

When we visit a customer site, we evaluate the customer’s needs based on several factors, including, but not limited to:

- Sizing of material

- What the customer is making with the material

- Material conditions, dry, wet, sticky

- Amount of clay content.

- Bulk density

- Plant layout and the existing equipment’s footprint

GK’s team operates on a boots-on-the-ground approach; each site varies a little bit. We go through a list of questions about your applications and then come to the conclusion of what style screen and modifications would be best for your operation.

For example, recently a customer had expanded their plant and was processing greater tonnages per hour. They needed a replacement unit that could fit into a tight footprint while screening more materials to meet higher processing requirements. Using an EFD, we fine-tuned the speed to process more quickly without exceeding the equipment’s design parameters.

How has the Industry Changed for Producers?

The biggest changes have been in the flexibility, or lack thereof, of product grades. Recently, many asphalt and concrete producers have been requesting specific gradations for each of their product mixes. As that becomes a more common practice, aggregate processors have had to adjust their material handling processes to waste as little as possible while also meeting the requirements for asphalt and concrete producers. Being able to adjust screening speeds is one way GK’s aggregate equipment helps aggregate processors appease several different types of customers with specific requirements while still reducing waste.

Going forward, the specs are going to continue to tighten, especially as the prices of raw materials continue to go up. Especially for state buyers who need high-quality aggregate mixes for long-lasting roads and construction projects.

Using flexible technology is the best way to mitigate a lot of these challenges. Whether adjusting automatically or manually during shift changes or weight adjustments. Understanding the producer’s site and customizing screens for them is the best way to stop these issues and future-proof your setup.

Technology Trends and Predictions

Regardless of whether it’s vibratory equipment, crushers, or other technology, vibration analysis tools have been on the rise—things like sensors and vibration monitoring software. More and more companies are trying to stay ahead of maintenance using vibration monitoring technology. Using these technologies, maintenance teams can monitor trends in vibration to predict when equipment isn’t performing properly more reliably compared to procedures like an oil analysis.

It’s already being used a lot more by our customers in the mining market. Typically, these new technologies first emerge in the mining market before being rolled out into the aggregate market over the next few years. So I think a lot of producers and OEMs are going to start adopting this technology more alongside the equipment they sell. GK offers portable stroke monitors that mines are already using to monitor their equipment.

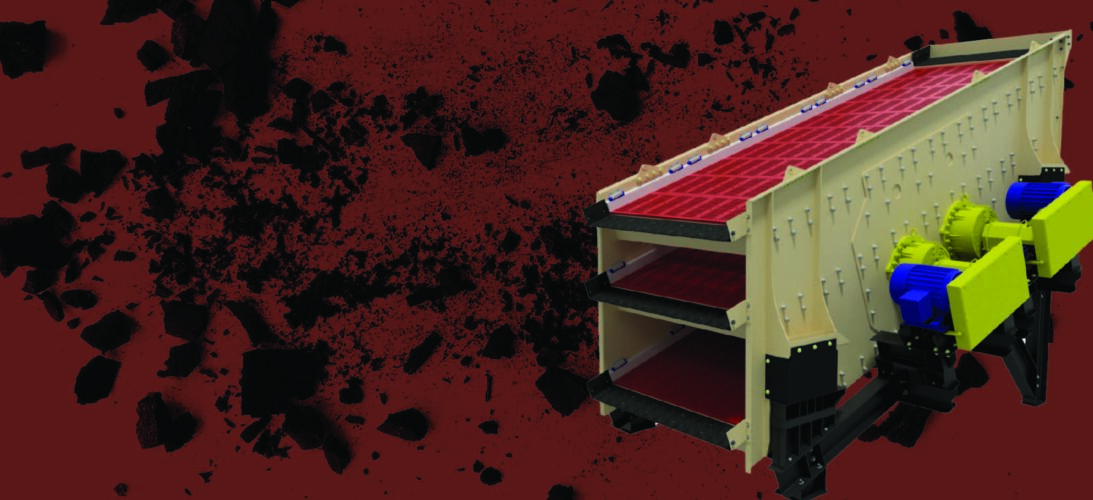

GK’s Two-Mass Difference

While there are numerous other companies that offer vibratory feeders and other aggregate equipment, GK’s equipment uses Two-Mass technology. As the name implies, Two-Mass technology utilizes two masses: a trough (second mass, i.e., body) and an exciter (second mass, i.e., drive). These two masses are linked together by a network of springs, creating a sub-resonant system that responds positively to material loading, unlike direct drive models.

But as you’re getting more load responsive or you’re increasing load where a traditional screen might bog down because of the increased weight, the two mass actually increases the stroke or maintains the stroke, and it’s accelerating usually through a program or even on its own to keep your efficiencies high on the products.

If you want to learn more about GK’s aggregate equipment and more aggregate industry news directly from industry experts, you can listen to the Drilling Deeper podcast featuring Elliott here.