Challenge

An aluminum disk manufacturer on the east coast was looking for a better solution to meter their product. This was not the only challenge though – they also needed to effectively convey the aluminum disks in two directions as well as distribute them to four separate locations.

Approach

General Kinematics was asked to come up with a solution for their distribution problem. The GK team assessed not only the workload, but also the area within which the system needed to be built.

Solution

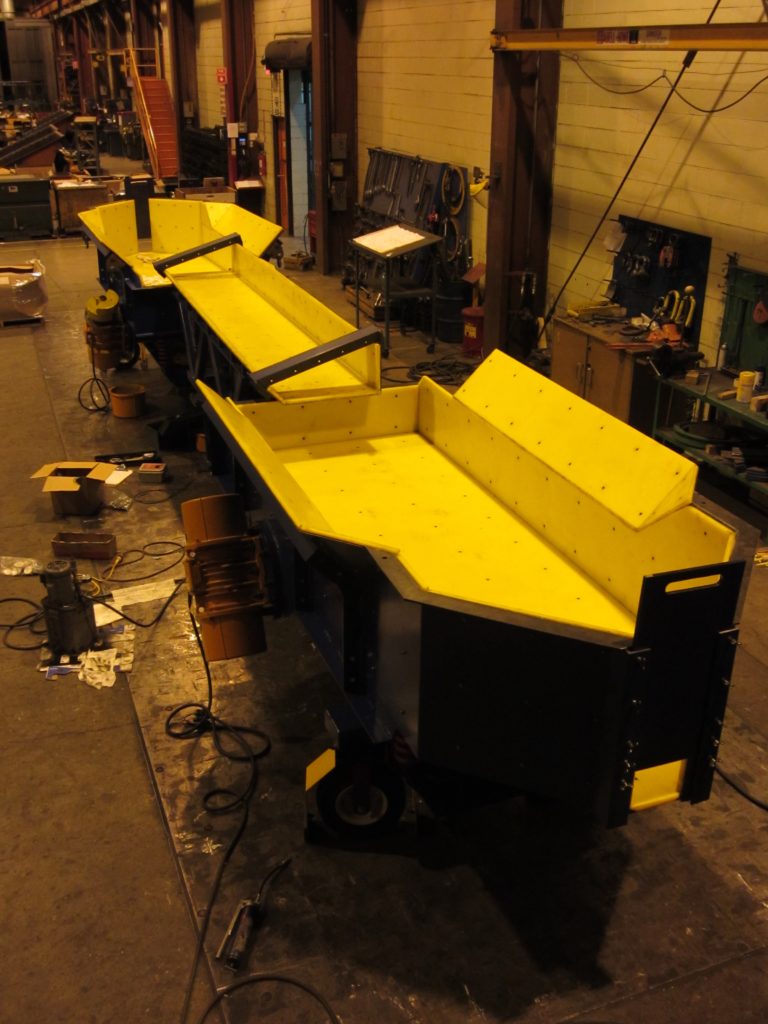

A Two-Way Feeder was first engineered to move the material in two opposite directions. Off each end of the Two-Way Feeder GK then installed a pivoting feeder that could rotate approximately 45 degrees to feed two of the manufacturer’s cleaning units. Designed with adjustable gates and plug stopped drives, the rotating feeders quickly stopped and efficiently kept disks from falling out of the unit while it rotated to another position.

Results

The first system was installed and put into production one year ago and has successfully accomplished distributing the aluminum disks in four separate directions. The customer was so impressed with the results that they purchased a second system six months later – and a third system which was just delivered.

About General Kinematics

General Kinematics Corporation, incorporated in 1960, was established to market, design, and custom fabricate innovative vibratory materials handling and processing equipment. Today the company is one of the world’s largest suppliers of vibratory processing equipment, holding more than 200 worldwide patents, and is acknowledged as a major contributor to the technical advancement of vibrating equipment design and application. Today, over 50,000 General Kinematics units have been installed in virtually all of the world’s industrialized countries. For more information about General Kinematics products and services, visit the company’s website at www.generalkinematics.com.