The Battle Continues…

Challenge

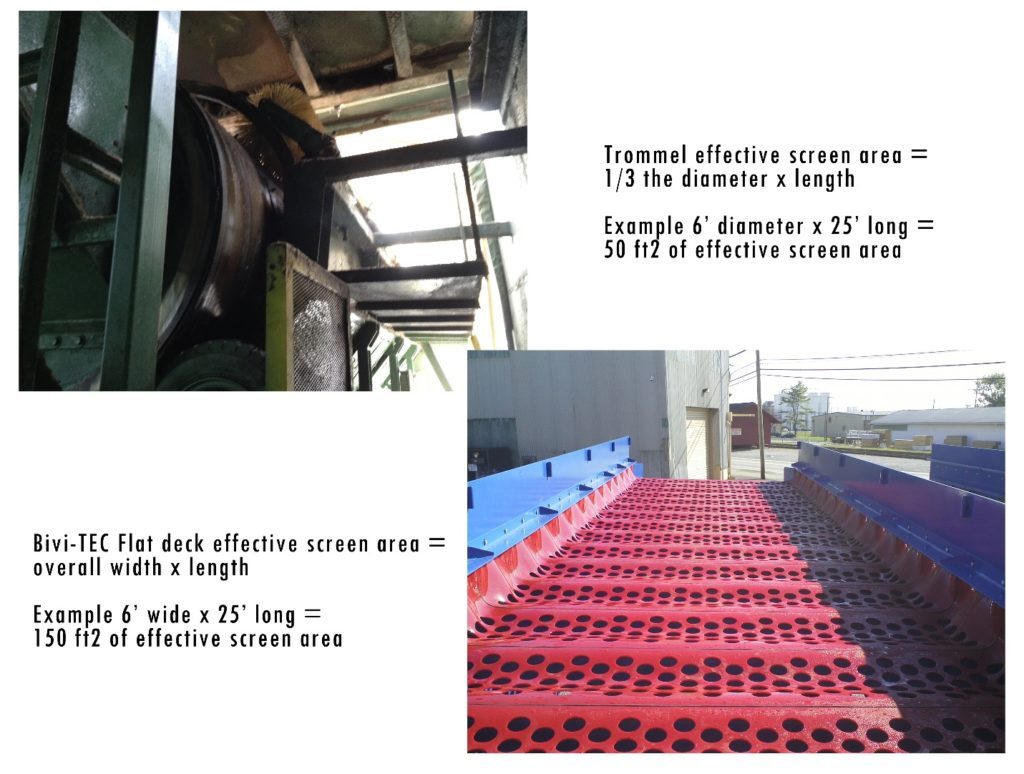

A southeast construction and demolition (C&D) recycling facility was operating a rotary trommel screen as part of their outdoor C&D recycling operation. The trommel screen works through its cylinder shape to spin material that is fed through the machine. The revolving screen allows wet material to tumble around and in the process, materials are separated and sorted from each other. The rotary trommel screen, which in this instance was used to screen out the -1/2” fines material from the -2” fines, was worn out after only 4 years of service. Needing a full drum body replacement, the facility realized a new unit was more cost effective than attempting to repair the existing trommel. A replacement was needed immediately.

Approach

Given General Kinematics’ reputation and history with the customer, the facility manager approached GK for help. GK realized that the best solution would not only be to replace the trommel screener, but to incorporate a larger overall effective screening area. Further, GK realized they would need to utilize a screening media/deck design that would minimize build-up and sticking of the fines, thereby minimizing down-time and cleaning/maintenance.

Solution

The solution was the GK Bivi-TEC® Fines Screen – one of our favorite flat deck screens. Working with GK to craft this unique screen design, the solution meant the -1/2” fines could be properly recovered, and the flexible polyurethane screen mats allowed optimal screening performance while eliminating blinding and plugging. Lastly, this style of deck design provided a much larger screen area than the existing Trommel with a similar overall footprint. This translates to a higher capacity throughput, more effective screening, and overall a cleaner operation for the site. A Slam Dunk!

Results

Earlier in the project, the customer had the opportunity to run their specific material over a mobile/truck mounted test Bivi-TEC® unit prior to their decision. This allowed them to create a large enough sample of material to properly qualify it with their end markets and confirm the results were as expected.

A new unit was installed in November 2014 and has been providing the desired end material the customer has been looking for at a much higher capacity rate. And even more exciting? They have eliminated the headaches they previously experienced with their previous rotary trommel screen.

This is just a small example of technology & process improvements that General Kinematics can deliver for end users. Consider getting rid of Trommels in the future and go to flat deck screens for a more effective screening solution in many ways! Contact General Kinematics to see how we can work with you to update your machinery and get the best results.

General Kinematics offers bivi-TEC® in partnership with AEI, a licensee of Binder & Co., AG.