With reduced commodity pricing being a recurring theme lately for the non-ferrous metal scrap industry, scrap processors are looking for a way to increase their return on investment without spending large amounts of capital on additional resource recovery systems.

General Kinematics has joined with their ASR customers to find the answer to increasing the recovery of the waste materials with the minimal amount of recovery equipment. After processing materials through different vibratory equipment tests, General Kinematics discovered the optimal process: grind up the rock and glass into a fine powder.

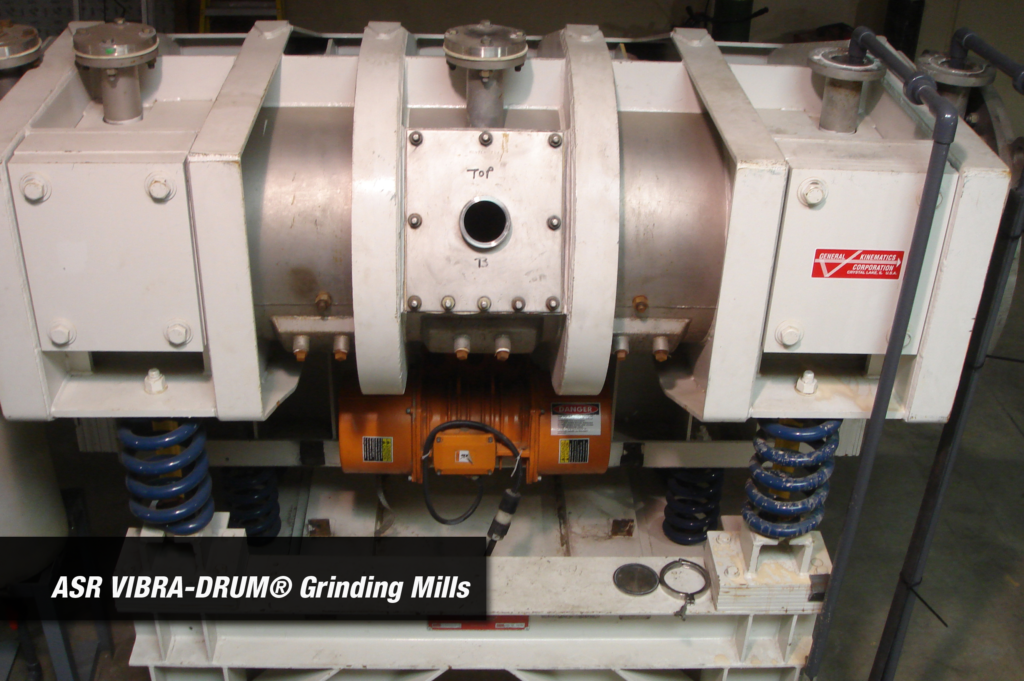

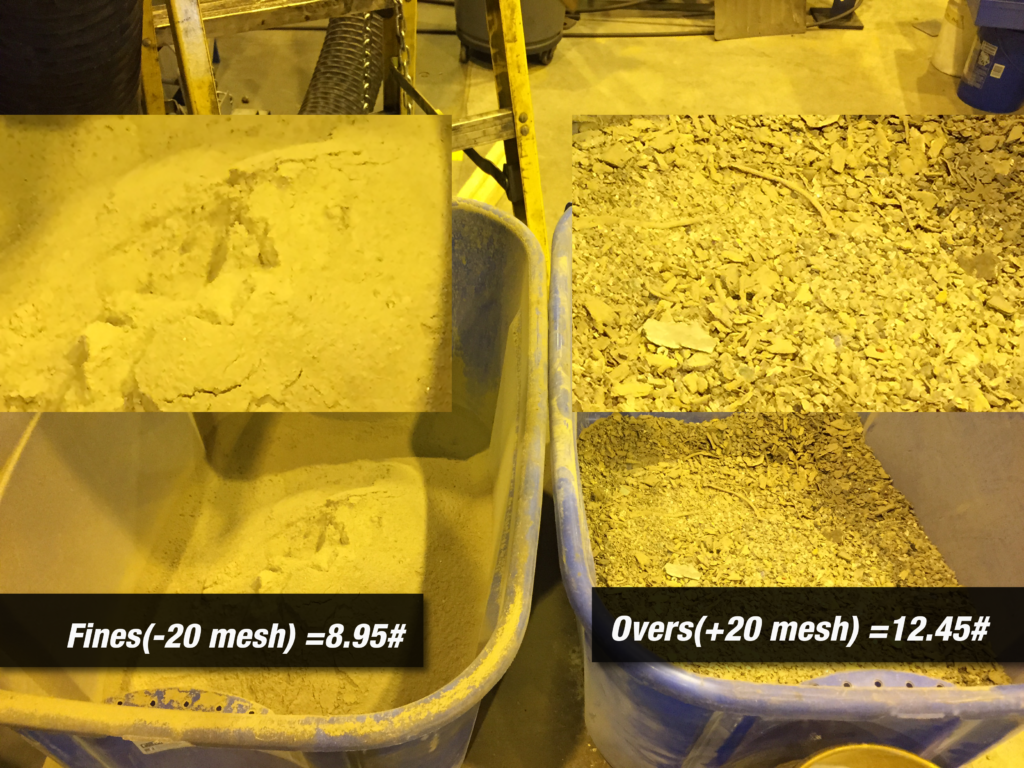

The test consisted of taking a previously waste stream material consisting of glass, rock, dirt, plastics, rubber, wire, and non-ferrous metals and processing them through the GK ASR VIBRA-DRUM® Grinding Mill. The ASR VIBRA-DRUM® Grinding Mills with its sub-resonant, Two-Mass drive and spring system refines the waste into a powdery “fines” fraction, while preserving the valuable metals.

The combination of the dry processing of material using an ASR VIBRA-DRUM® Grinding Mills along with GK’s High Stroke Feeder (HSF) and various two-mass screening technologies could be a potential opportunity for increased revenue for scrap processors.

The HSF vibratory action spreads the material across the full width of the pan, thinning out the burden depth, creating separation and making the subsequent sorting equipment more effective. To learn more about the HSF, and how it is proven to increase purity rates 5.% check out our High Stroke Feeder white paper.

The ASR VIBRA-DRUM® Grinding Mills has been proven to successfully break down rock and glass leaving precious metals intact. The fines powder can then be easily screened to achieve a concentrated metals stream. This increases the efficiency of subsequent equipment increasing profits, and reducing your landfill costs. Interested in learning more? Send GK your scrap materials for testing to determine whether the ASR Grinding Mill is a solution for you.