CHALLENGE

A Midwestern scrap yard needed to reclaim the steel on the ground of their yard and presented three challenges to General Kinematics for a turn-key system:

- Receive and meter product (scrap steel sized 2″ to 60″, clay/dirt, wire/fluff, and organics) for processing.

- Size and isolate product 0″-1/2″, 1/2″-4″, and 4″ and above then then transfer this to individual storage bunkers.

- Provide suitable sorting arrangement for removal of non-ferrous product from the 4″+ product stream.

APPROACH

APPROACH

General Kinematics utilized years of experience, yet provided testing to validate the process of metering. When in consideration of the screening process, however, General Kinematics needed a unique solution to handle their heavy product. The screen also needed to handle the clay intensive soils that would blind most screens in a matter of minutes.

SOLUTION

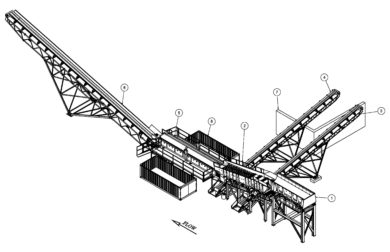

General Kinematics field tested and presented a solution utilizing heavy, yet flexible, rod deck screens to screen all 1/2″ product immediately and discharge to a GK provided belt conveyor. The same unit then utilized 4″ finger deck sections to remove the mid-size product to another belt. The remaining 4″+ product was then discharged to a short pick belt for removal of stainless and aluminum product. The remaining ferrous material discharged to a stacker belt for collection and subsequent shipment.

RESULTS

The GK turnkey solution has now been in service for 4 years and continues to operate successfully and without incident. The solution provided continues to allow the yard to reclaim, particularly even after wet/snowy weather, the entire pile including that which has been reclaimed into the soil.

About General Kinematics

General Kinematics Corporation, incorporated in 1960, was established to market, design, and custom fabricate innovative vibratory materials handling and processing equipment. Today the company is one of the world’s largest suppliers of vibratory processing equipment, holding more than 200 worldwide patents, and is acknowledged as a major contributor to the technical advancement of vibrating equipment design and application. Today, over 50,000 General Kinematics units have been installed in virtually all of the world’s industrialized countries. For more information about General Kinematics products and services, visit the company’s website at www.generalkinematics.com.

APPROACH

APPROACH