Customer wanted to automate and optimize an old process that increases the leaf factor of tobacco. The new technology must be able to fit within the existing physical constraints of the plant structure without redesign of the facility.

Approach

General Kinematics was approached by the customer to qualify their process. Through the qualification, GK demonstrated that a properly designed vibratory fluid bed dryer would achieve the results they required, and improve the quality of their end product.

Solution

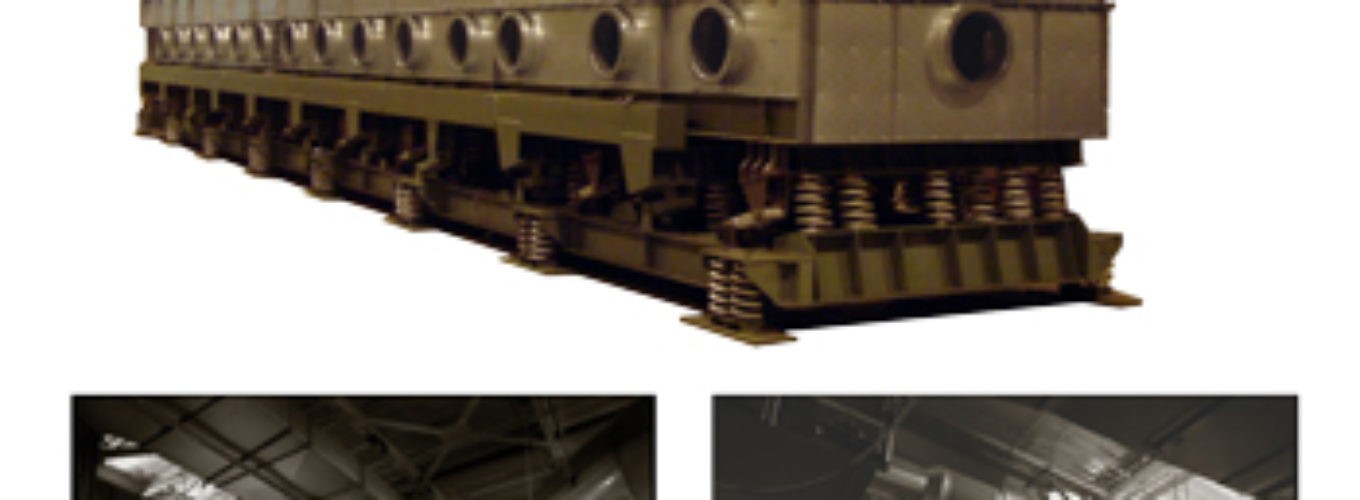

Within six months GK’s Engineered Products Group designed, built, and delivered a turn-key system incorporating a 600 square foot fluid bed processor which exceeded lab pilot test outcomes by 10%. Achieved near-optimal utilization of resources in re-designing one of the largest vibratory fluid bed systems in the industry.

Results

The resulting installation of General Kinematics Vibratory Fluid Bed Dryer increased plant capacity, reduced overhead costs by 66%, and increased profitability of the customer, all while maintaining a high standard of quality.