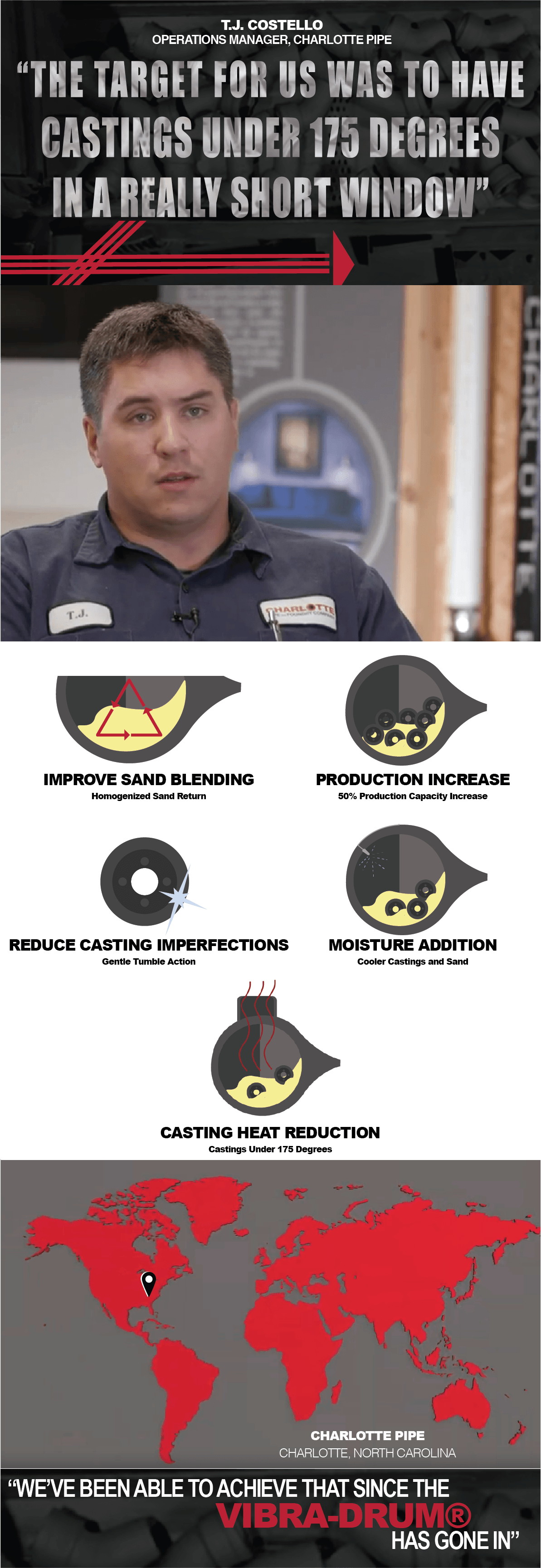

Charlotte Pipe, one of the nation’s top pipe suppliers takes you on an inside look through their facility and their VIBRA-DRUM® Sand Casting Conditioner from General Kinematics. Charlotte Pipe was looking to increase their production from 80 molds to 120. In addition to this process improvement, they needed to achieve mold temperatures under 175 degrees Fahrenheit in a short time frame.

After installation of the VIBRA-DRUM®, Charlotte Pipe has seen cooler castings, improved homogenized sand return, and a reduction in casting damage. Utilizing the recovered molding sand to gently tumble the castings, the heat is displaced into the sand while the moisture addition system adds moisture to the sand and dispels heat through evaporation. Charlotte Pipe has seen the process improvements the VIBRA-DRUM® has to offer. Watch this video for the full story: