Vibratory conveyors, when broken down to their key elements, are very simple looking machines. There is typically a trough, a frame, some springs, and a means of creating vibration through an eccentric shaft. When these elements are put together, materials usually are predictable and will convey down the straight line from point A to point B.

However, when you take that straight conveyor and curve it, the design of the machine turns from a simple concept to a more complicated design. This complication comes from wanting to keep the material you are processing on the same trajectory at the end of the curve as it had at the beginning of the curve.

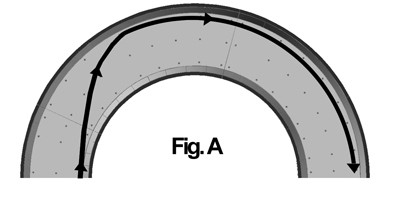

When you look at curved conveyors from other manufacturers, the path of the material resembles the material path shown in Fig. A. As you can see, the conveyor causes the material to ride on the outer edge of the conveyor trough, causing material bunching, material damage, inconsistent feed rate, and poor material spread at the discharge of the vibratory conveyor.

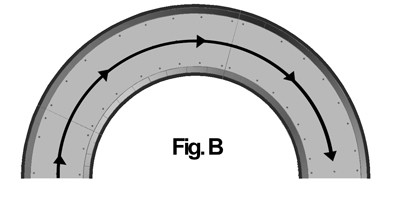

General Kinematics proprietary conveyor designs keep your material conveying in an optimal path throughout their journey through the curve. As shown in Fig. B, material follows the desired trajectory throughout the curve, and maintains a consistent conveying speed.

The “GK Live From the Lab” video below shows a General Kinematics curved vibratory conveyor during it’s 20 hour run off in our factory. Watch as the socket that is on the conveyor follows the bolt pattern of the trough. You will also notice a consistent conveying rate, and the smooth motion of the conveyor, which quietly conveys the part without bouncing or tumbling.

For the best vibratory conveyors in the world, nobody comes close to General Kinematics. To learn more about GK’s vibratory conveyors, click here…