Late last year GK helped the Auto Industrial Group in South Africa upgrade and install new equipment and systems for its two cast iron foundry operations in Isando and Wadeville, Gauteng.

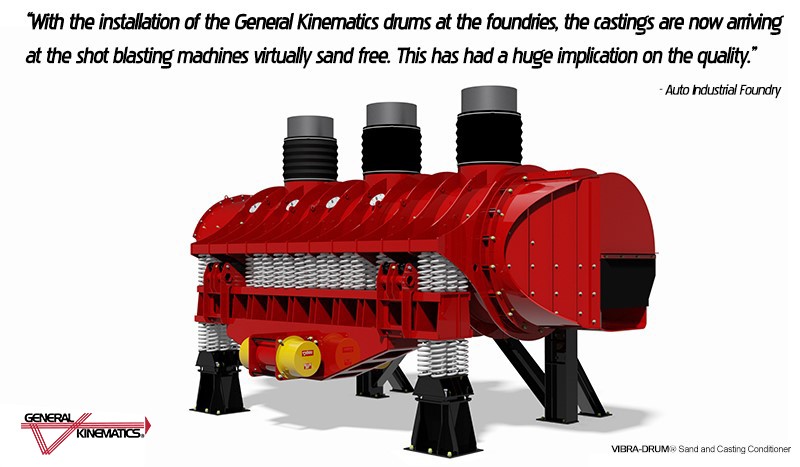

This install/upgrade included the addition of the General Kinematics VIBRA-DRUM® Sand and Casting Conditioner as part of their shakeout operation. Why is this big news? Because the Auto Industrial Group is a main supplier for all of the original equipment manufacturers (OEMs) in South Africa.

“At both foundries we have installed a new General Kinematics VIBRA-DRUM® Sand and Casting Conditioner in the shakeout operation. This includes the conveyors and agitation systems post and prior the drums. The gentle tumbling action of the drums keeps the castings in a bed of sand, never dropping or creating impact during the shakeout process and it eliminates any mechanical damage.”

As a smaller operation in a competitive international auto OEM market, volume and quality matter. That’s why the Auto Industrial Group trusts and relies on GK equipment.

Andrea Moz Managing Director/CEO of Auto Industrial was thrilled with the results of the GK equipment stating that, ”… we have achieved all the objectives that we were looking for before installing the drums.”

Check out the full Castings SA article here to learn more about the General Kinematics VIBRA-DRUM® installation.

If you have questions or would like to learn more about GK’s full line of vibratory equipment for your foundry, contact us today!!