When it comes to investing in new capital equipment, businesses today are constantly challenged with making a value determination between cost and quality. Should they spend more to buy a higher quality machine, or save money and purchase an adequate machine that may or may not provide the uptime and longevity that they would like, but that will get the job done at a minimum acceptable level?

As a manufacturer, we too have to weigh these decisions when looking at capital equipment investments in our manufacturing facility. Should we invest in the best money can buy, or save a little now and go with the value option? Whenever I am personally presented with this dilemma, I am reminded of an old saying that my father likes to share in these situations:

“Quality is like buying oats. If you want nice clean, fresh oats, you must pay a fair price. However, if you can be satisfied with oats that have already been through the horse, that comes a little cheaper.”

While funny, there is a lot of truth in this statement. If you expect to purchase a premium product, you should also expect that it will cost more. However, with that cost, you should also expect premium service and extended product life. If you choose to purchase a product of lesser cost, you shouldn’t be surprised that the company providing it does not support you as well as they should.

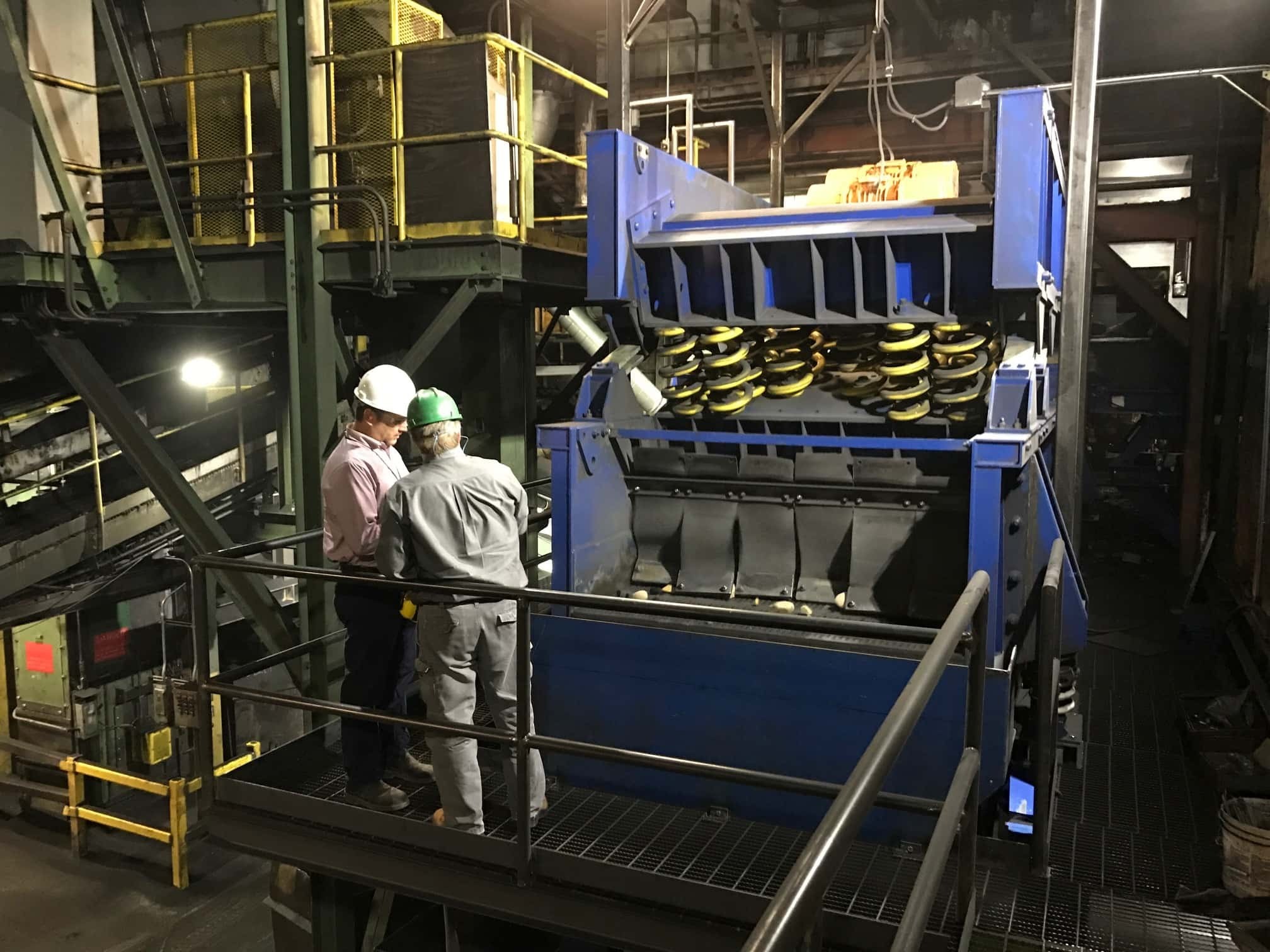

General Kinematics has been working hard to provide quality for the past 57 years. With engineers dedicated to continual improvement and specialists that listen to what our customers are looking for in their equipment, the GK family never stops striving for exceptional quality, not only in our machines, but our people too.

When working with GK we recognize every project is different, and with almost six decades of experience at our back, we are always up to conquering a new challenge. Whether you only have a specific amount of room in your facility or have a hard-to-handle material you are trying to process, our people have the skill and experience to engineer your best fit.

Because of this innovative passion for advancement, GK has developed amazing products for every field and engineered and built them to last longer and be more productive for you. We make it our business to know that our customers are getting the most out of our equipment. We offer on-site service, complimentary training, and survey our customers for feedback to develop the next generation of high-quality vibratory equipment.

When looking to purchase a new machine to tackle part of your line, you don’t want a band-aid or stand in. You want a permanent member of your processing team to increase your production and profits. At General Kinematics you get what you pay for: a quality engineered and manufactured machine that will be an amazing addition to your team and a processing powerhouse to last.