Metal casting has been entwined with the United States from the very beginning, driving the westward journey into the industrial revolution and making its way today in the ever improving world of automobiles. Foundry has truly been at the heart of America, providing the materials for our cars, farming equipment, and much more.

One of these foundries embedded in the history of the United States for five generations can be found past long stretches of country roads in the eastern corner of Illinois. Rowe Foundry made its start in river clamps in the late 1800’s, improving the effort to expand oil and gas pipelines across the US by allowing them to be weighted into bodies of water. With modern technology, this foundry has made its way in engineered castings to create tractor frames, gate valves, and gearbox housings just to name a few.

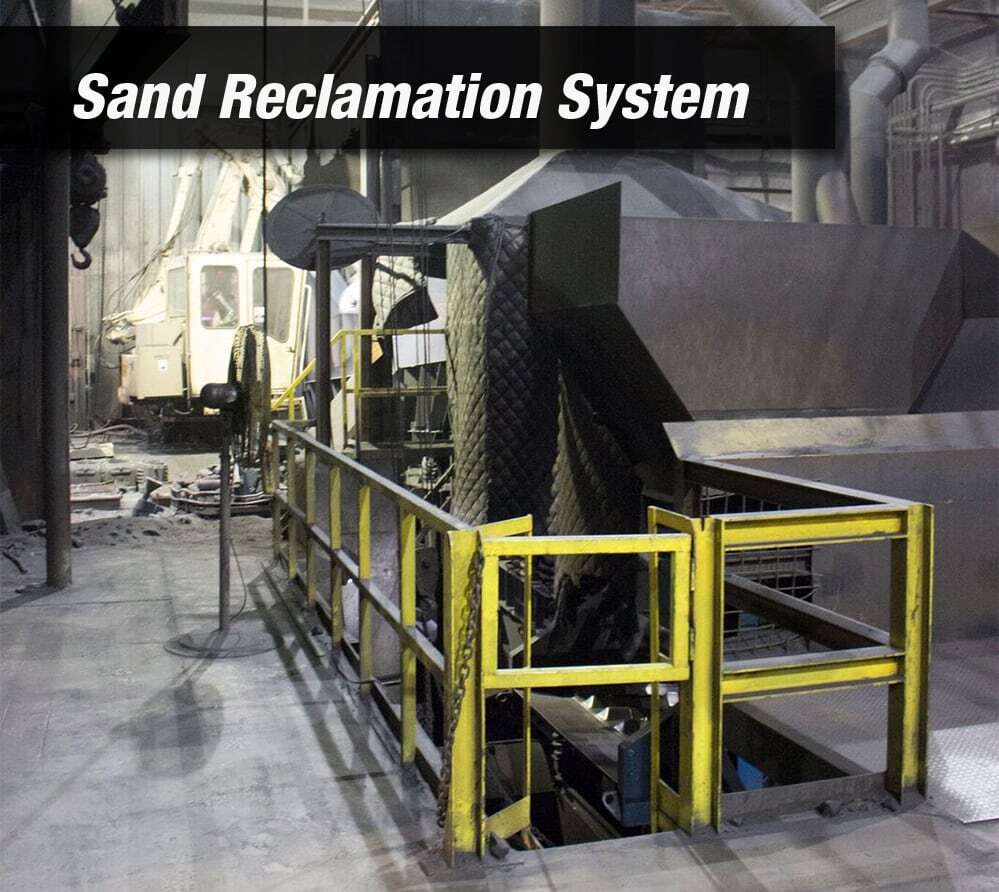

Having been in the foundry business for over 100 years, Rowe has seen their fair share of No-bake foundry equipment come through its doors. General Kinematics is proud to be the brand of choice when it comes to their casting handling and sand reclamation system.

Rowe Foundry came to GK when they were having issues with their shakeout. The competitor’s unit had issues from start-up, needing to be rewelded at every shutdown among other issues. After trying to resolve the issue with no success, the Foundry reached out to GK in search of a solution.

General Kinematics custom engineered a Two-Mass Shakeout and VIBRA-MILL® Vibratory Batch Sand Reclamation to handle the job. The shakeout and VIBRA-MILL® Vibratory Batch Sand Reclamation were installed and after a few adjustments resolved Rowe’s issues. The equipment not only provided a smaller footprint but broke the sand down at a better rate. When asked how the equipment had been performing, Larry Norton, Vice President of Rowe Foundry said: “The scrubbing sand is much improved and the LOI’s have decreased. It’s working well for what we are doing here.” After asking if they had any issues Larry quipped, …”you haven’t heard from us and I think that’s a great sign.”

General Kinematics is proud to be a part of this historic foundry along with other foundries across the globe. Improving the foundry process has been our goal since 1960, and GK has worked tirelessly to care for your castings from melt to market. Let us know about your company story, make a comment below!

Looking to improve your foundry’s efficiency? Talk to our engineers today!