If you have heard your customers complain about having lumps in your powder and bulk material you are not alone and, the odds are you have lost a few customers to a company, they claim, “never has lumps”. Even if you happen to have a state of the art system or the best product on the market customers will consider agglomerations as a sign of bad product.

The truth is materials forming agglomerations is normal and can be caused by multiple scenarios including:

Moisture Caking

Material Bond

Chemical Reaction

Static Electricity

There are many ways you can try to improve your product conditioning, from controlling the moisture or temperature in a room to making changes in your pre-packaging process. These changes can cause headaches and may not improve a amount of agglomerates completely. In fact, a lot of these lumps and bumps can be formed in the transportation process leaving you with stiff, rock-like bags to distribute to your customers.

In some cases, this can add an extra step to the distribution process causing the need for employees to physically break up the bags with hammers or dropping the product over and over until they slowly de-clump. This process can be not only an enormous waste of time for employees, delaying your distribution process, but also cause back injuries and other health related issues for your team.

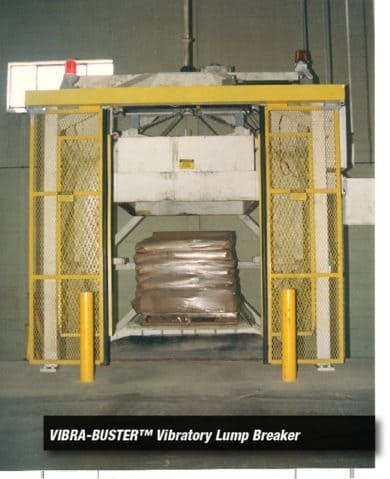

General Kinematics has devised a vibratory system to eliminate this agglomeration epidemic while preserving the quality of your product. The VIBRA-BUSTER™ Vibratory Lump Breaker can rid up to an entire pallet of agglomerations in minutes. By placing the pallet of material on the equipment the VIBRA-BUSTER™ Vibratory Lump Breaker shakes the material loose while keeping the bags in tact.

The VIBRA-BUSTER™ has proved itself time and again with many bulk powders such as fertilizer bag de-lumping, flour, sugar, sand, and more… including a new application Coming Soon!

To learn more about what the VIBRA-BUSTER™ can do for your material, contact GK!

Our team is always on the lookout for a new challenge. What process challenge could this solve for you?

Discover GK’s other bulk and processing equipment that can do everything from:

| Activation | Agglomeration |

| Coating | Compaction |

| Conveying | Cooling |

| Crushing | Delumping |

| Dewatering | Drying |

| Elevation | Elutration |

| Feeding | Grinding |

| Loading and Unloading | Material Beneficiation |

| Metering | Mixing |

| and More |