Challenge

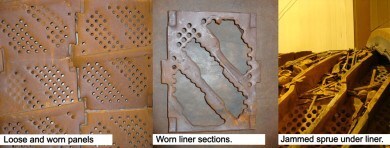

A leading North American metal caster had an existing rotary drum that was in need of replacement. The drum was being utilized to clean and break up sprue prior to returning to the melt department. The cast liner system in their drum had worn out, which jammed the area between the liner body and liner with sprue and tramp metal. This caused jam-ups in the process and accelerated wear on the drum body.

Approach

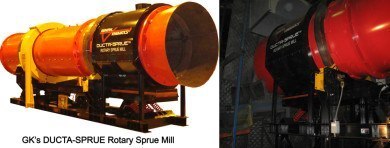

Looking for an easier-to-maintain solution, the foundry’s maintenance and engineering team met with General Kinematics to discuss the all new DUCTA-SERIES™ rotary drum line. The customer wanted easy to maintain liner sections, and to avoid having to patch and replace the drum body in the future.

Solution

General Kinematics took their old drum as “trade-in”, then engineered and installed an all new GK DUCTA-SPRUE® rotary sprue mill, which utilized GK’s heavy-duty bolt in drum liner system, as well as a vibratory sand return conveyor. The combination of these two technologies addressed the maintenance concerns the customer experienced with their previous rotary machine.

Results

After almost a decade of operation, the maintenance team at the foundry contacted General Kinematics to order their first set of liners. The original liners were starting to show some wear, so the maintenance team proactively ordered replacements so they would be ready.

Below are pictures of the original thickness of the drum liners and the thickness of the liners after 10 years, as well as the condition of the drum body: