The customer was looking for a unique solution to replace their existing vibratory shear take away conveyor. Every so often the shear would not fully shear off the material correctly. By design, the shear would then index the piece forward. If this happens several times in succession, the extended piece would be leveraged onto the vibratory conveyor which deformed the trough pan overtime. In addition, the large downward force would restrict the vibratory conveyor’s motion, causing damage to the supporting rocker legs and drive assembly.

Approach

While the customers previous vibratory equipment supplier had much experience with these types of systems, they could not offer any new solutions to help resolve it. GK was approached to offer a unique solution in a timely manner.

Solution

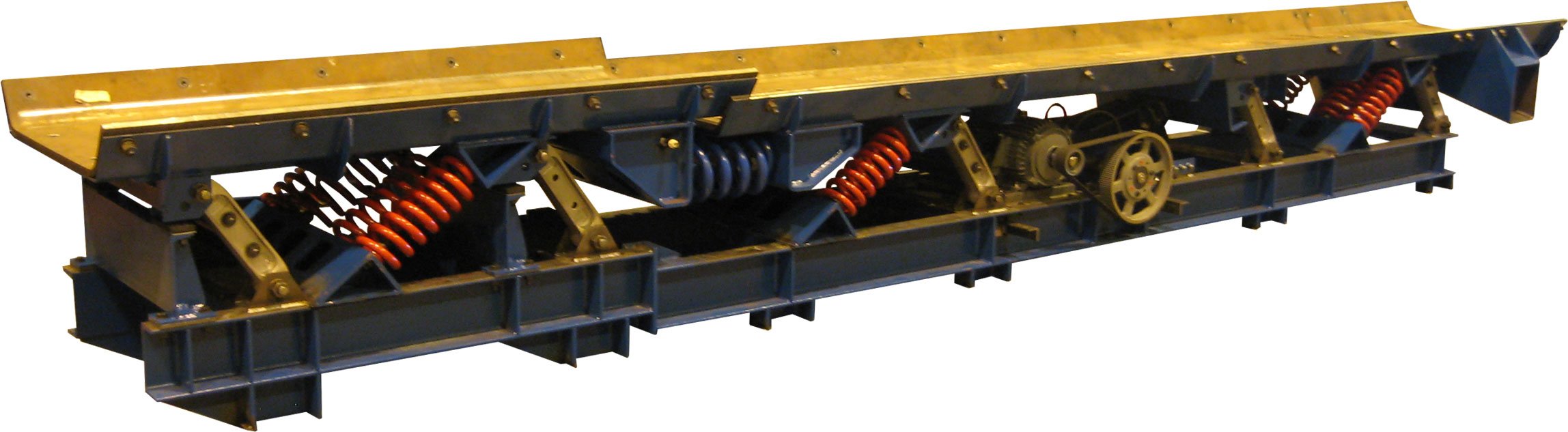

Several ideas were discussed at General Kinematics on how best to resolve the customer’s problem. The resulting vibratory equipment design provided for a slave driven vibratory conveyor trough at the feed end of the vibratory conveyor, in conjunction with a motion switch to detect the jamming condition. The slave trough is connected to the main vibratory conveyor trough by an engineered coil spring. Under normal conditions, the two sections run in unison, transferring any material from the feed section to the main conveyor seamlessly. However, should the indexing / jamming condition occur, the feed end would then be reduced in amplitude until it would bottom out against safety bump stops. At this time the motion switch will trigger a signal to the operator warning of the condition so that it can be addressed before any damage occurs. The main trough can continue to run while the engineered coil spring between the main conveyor and the slave trough section absorbs the differential displacements.

Results

When challenged with a unique and unusual process condition that other vibratory companies could not solve, the talented engineering staff of GK was able to leverage their extensive process and vibratory equipment design knowledge to create a new equipment solution that eliminated the customers process problems.