The World Stage

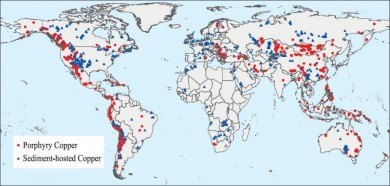

Copper is mined around the globe with millions of tonnes being produced annually. Utilizing technology that can increase overall recovery rates and lessen the environmental impact has significant value.

Acid Rock Drainage is a reality for many mines producing copper. According to Miningfacts.org, sulphidic tailings are the discharge from the copper extraction process. These tailings are stored in large outdoor piles and acid rock drainage (ARD) occurs when the tailings are exposed to rain water and oxygen. The ARD water contains sulfuric acid as well as valuable dissolved copper leached from the tailings.

The GK Solution

Copper recovery from ARD can be achieved with simple chemistry and the technical advantages of the GK VIBRA-DRUM® . This vibratory drum can easily fit within an existing system and works by aggressively driving a mechanical and chemical process.

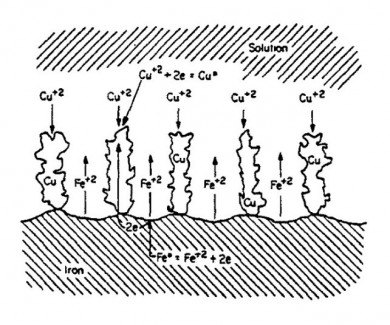

Chemically the spontaneous reaction, called copper cementation, is achieved within the drum. Theoretically, for each kg of copper cemented, .088 kg of iron is consumed. However, in reality, iron consumption amounts to an average of 1.4 to as much as 3.2 kgs per kg of copper produced (Ref: Mineral Sciences Laborites article). Mechanically, the iron media in the VIBRA-DRUM® makes continual impacts (millions per minute, due to the intense vibratory action only GK equipment can achieve). This frees the copper plated onto the iron media into flakes which are suspended in the ARD water and discharged from the drum then recovered by filtration following the drum.

Iron media is added on a regular interval to sustain the chemical reaction and recovery of the copper. This process occurs continuously, and has resulted in upwards of a 90% copper recovery rate.

Final Word

The addition of the VIBRA-DRUM® equates to a significant increase in revenue from what before was a waste water stream. A full list of GK mining solutions is available at www.gkmining.com.

View the article as a PDF here: Copper Recovery from ARD.