The passage of time has seen many technological advancements in mining equipment, and these have made mining processes more efficient. These advancements, such as developments in machinery created by General Kinematics, have aided in the growth of the sulfur mining industry.

Historical documents mention sulfur as far back as early biblical times when it was referred to as “brimstone”. In Ancient Egypt and Greece, documents refer to sulfur as being used for medication and fumigation.

The once primitive mining methods used during earlier times have developed with the invention of modern-day equipment that makes sulfur mining more efficient and cost-effective. Likewise, the mining equipment used today helps reduce waste and chemical exposure.

The Basics of Sulfur Mining and Processing

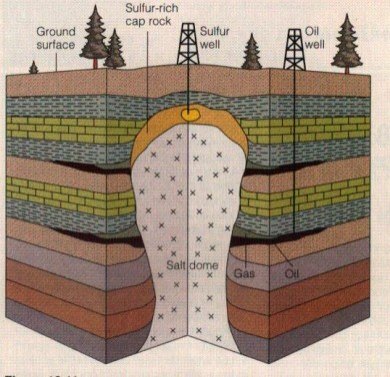

Once found in volcanic regions and on salt domes, these are no longer the typical locations used by commercial sulfur mining companies.

More modern methods of sulfur production started as by-product resulting from other industrial processes, such as oil refining. The natural element has also been found in fossil resources, such as natural gas and petroleum.

What is Sulfur Used For?

- Matches

- Fireworks

- Black gunpowder

- Rubber vulcanization

- Insecticides and fungicides

- Medical treatment for certain skin diseases

- Glass production

- Cement mixtures

- Adhesives

- Sugar refining

Where is Sulfur Found?

Ijen, a quiet but active volcano in East Java, Indonesia contains a one kilometer wide crater lake; a well known site of sulfur mining. Sulfur miners break off large chunks of sulfur from the crater floor and carry the chunks out in large baskets nearly 3 kilometers to town. This process is very labor intensive, and earns miners anywhere between $5 and $13 per day (USD).

The sulfur mined in East Java is processed nearby for use in bleaching sugar, vulcanizing rubber and other industrial processes.

The Sulfur Mining Process

From the late 1800s to the end of the 20th century, the Frasch process of sulfur mining was commonly used. This involved forcing super-heated water into a sulfur deposit so the sulfur would melt and come up to the surface by way of compressed air. During the latter part of the 20th century, mining or recovering sulfur as a by-product of natural gas production or oil refinement became more significant.

Over the course of time, sulfur has been one of the most basic mined materials used in industrial production processes, which have been made more efficient and cost-effective through the technological advancements of mining machinery.