Motors are the powerhouse or your equipment and they work strategically with the design and balance of your General Kinematics equipment. But how are General Kinematics motors different from others on the market?

There are a variety of reasons why GK motors are different from the rest. General Kinematics puts the same technical expertise into our motors as we do our equipment. GK engineers know the ins and outs of every application and a lot of it relies on your motor. Our motors are specifically selected and modified as necessary to handle the mechanical forces in play and to work in harmony with your equipment in the environment and application in which they are operating. Providing you with the highest performance possible, each motor has its own specifications.

Conveyor Motors

First up: Conveyor Motors are designed, built, and assembled to meet our G-force requirements. Motor leads are potted and junction boxes are packed to ensure that the wires do not rub and short out. They come with a special slide base designed by General Kinematics for vibrating applications.

Feeder Motors

Next, General Kinematics VIBRA-MAX™ Feeder Motors have two different categories: standard and explosion proof. Both have been specifically designed for GK equipment specifications. General Kinematics’ Two-Mass design uses the weight of the machine and motors working together to take advantage of natural frequency to create more work with less energy. As GK engineering has evolved over the past 60 years, so has our motor selection. General Kinematics is always ahead of the curve when it comes to our vibratory motor selection because we are constantly looking for better ways to harness the power of vibration for the benefit of our customers and their specific applications.

Why Explosion proof?…

Hazardous locations can provide special considerations affecting the health and safety of your employees that may work in those environments. Explosion proof motors are also extremely important to the health and safety of your employees. It is important to make sure that if you are working with a hazardous chemical, coal or in an extreme environment where explosion-proof motors are required that your motors are up for the challenge. As a component to these considerations, proper motor selection is critical when operating in a hazardous location. If your equipment is operating in a hazardous location, GK can provide solutions for most environments. Designed to meet or exceed requirements of the applicable certifying agency such as UL or ATEX.

Shaker Motors

GK Shaker Motors have been a staple at General Kinematics in heavy-duty applications for over 50 years. GK Shaker Motors are constructed to withstand extreme mechanical loads in these heavy duty applications. GK uses those many years of knowledge and experience to keep ahead of the standard. We want you to have the best motor for your application. Others have tried but failed. GK knows the right design to ensure they work symbiotically with our equipment.

Foot Mounted Vibratory Motors

Foot Mounted Motors, are ideal for certain industries. Several of these applications work best with the motor selected from the VIBRA-MAX™ line and include features such as wash down environments and protection from challenging environments. All Foot Mounted Vibratory Motors go through the same rigorous selection process taking advantage of our experience, and expertise when selected by GK.

Do’s and Don’ts of Motors

Do…

- FOLLOW THE MANUAL. It is extremely important that you follow the manual for the care and safety of your motor.

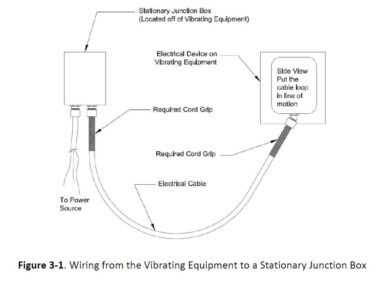

- Make sure the area around your motor is free and clear and that the electrical cable is correctly looped. Rubbing of the cable can cause premature failure and possible serious damage to your motor.

- Avoid extreme heat. Running your motor in extreme heat can cause the grease to prematurely fail causing premature bearing failure and possible overheating of the motor.

- Follow a greasing schedule. The schedule in the manual provides general guidelines. The experts at GK can help you tailor a schedule to fit your specific application.

- Make sure your motor is working in the correct parameters. If not, it may seem to be working, but at a detriment to your equipment.

- Special bearings, machining tolerances, and reassembly techniques. GK offers rebuilding services for electric motor care must be taken.

(There are a lot of good motor shops out there but very few have good working

knowledge of mechanical requirements for vibratory equipment.)

Don’t…

- Use a type of grease other than the one specified for your motor.

- Buy a motor without consulting your GK expert. Price difference is a major red flag.

- Modify your motor without consulting GK.

- Utilize a frequency drive without consulting GK. Improper use of frequency drive could cause severe damage to the equipment.

Always consult GK if making a modification. Your safety comes first! Have a question about motors? Call GK and talk to a motor expert!