Sand reclamation is the process by which foundry sand is reconditioned without significantly affecting its physical properties. During the sand reclamation process, binders and coatings that adhere to sand grains during casting production are removed to recycle sand for subsequent use. Thus, the sand must be cleaned to remove the binders that adhere to it during thermally intensive operations.

Typically, sand reclamation begins by grinding the mix of sand and binder formed during processing into grains. Then, dust-like particles and grains that are too coarse are removed via vibratory sand reclamation. Finally, grains of the correct size are cleaned and treated to remove as much binder and other organic materials as possible.

Common sand reclamation methods

There are three major types of sand reclamation processes: mechanical reclamation (i.e., attrition reclamation; e.g., dry reclamation), wet reclamation, and thermal reclamation. Mechanical sand reclamation methods like the VIBRA-MILL® Vibratory Batch Sand Reclaimer grind down the binders quickly to keep sand flowing through the foundry process. Wet reclamation partially removes sand coatings and organic matter, whereas thermal reclamation processes, which typically operate at over 600°C, are suitable for non-ferrous foundries and oil-bonded sands that do not contain clay.

Often, these reclamation processes are combined to improve sand recovery and quality. For example, sand may be processed using thermal reclamation after wet reclamation to completely remove organic matter and restore the original quality of the sand.

Why is sand reclamation important?

Sand reclamation is vital in the metal casting process because it can help reduce costs without negatively affecting casting quality. Once a sand reclamation process is in place, a foundry can significantly decrease the amount spent on fresh sand over the subsequent months and years.

Additionally, sand reclamation can reduce the environmental impact of the process. In recent years, because sand is a major component in building and construction due to its use in concrete and asphalt, there has been a world-wide shortage of sand. This may seem counterintuitive, but because desert sands are often too fine for industrial purposes (and too far from the sites that require the sand), there is a limited amount of sand that can be used.

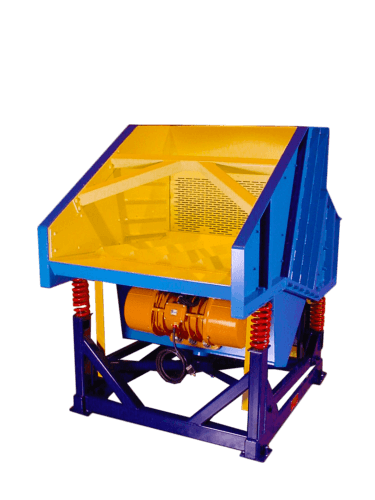

The VIBRA-MILL® Vibratory Batch Sand Reclamation

The VIBRA-MILL® Vibratory Batch Sand Reclamer is an energy- and space-efficient vibratory unit that prolongs the use of No-Bake Sand reducing the need to purchase new sand. The low-maintenance unit can handle over 50 tons per hour reducing lumps down to minus 20 mesh. The VIBRA-MILL® unit is also available in a totally enclosed design to remove silica dust from the workspace helping your foundry reach current OSHA Silica Guidelines.

Every foundry has a unique process, and with that unique process is the inherent need for a tailored solution. The General Kinematics team engineers and builds flexible equipment for every process. Contact us for more information about sand reclamation solutions at General Kinematics.