Challenge

A Canadian gold mine was looking to partner with a vendor that could meet their standards for optimizing their process and a machine capable of handling their increased production volume, with lower overall operating cost. They needed a unit that could accomplish the grueling task of sorting their extracted materials to a size of 22mm and that could handle the high capacity abrasive material moving over the screen 24 hours a day 7 days a week.

Approach

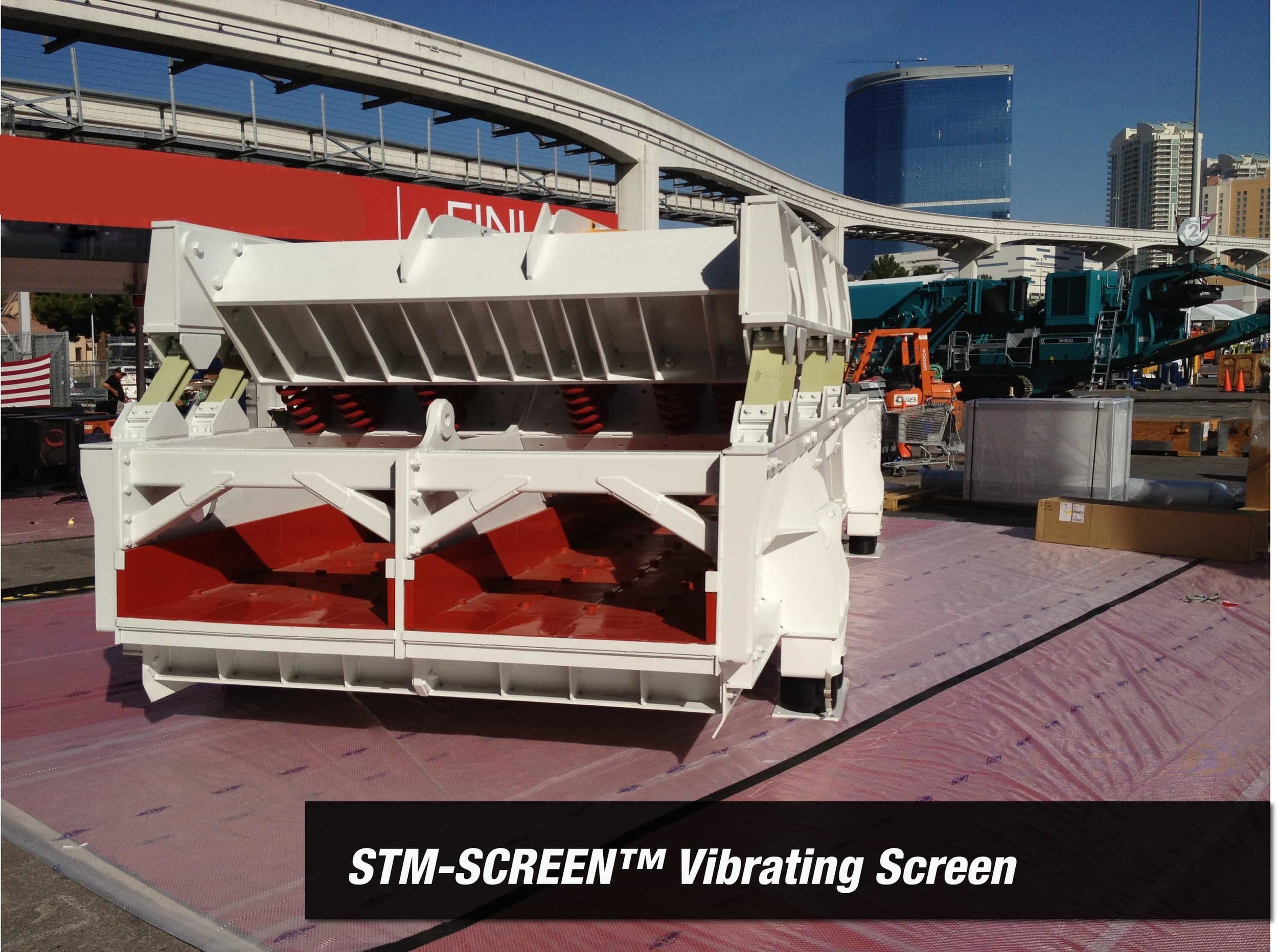

This customer was not familiar with General Kinematics but intrigued by the Two-Mass system and the potential it has to handle the rugged conditions of mining aggregates. The STM-SCREEN™ screen’s ability to respond to load surges and increase current capacity limits fit the processing requirements they were looking to achieve.

Solution

The STM-SCREEN™ Vibrating Screen proposed was designed with two polyurethane decks and a light misting function on the bottom deck for dust suppression. The polyurethane decks allowed rocks that traditionally were easily trapped to wriggle free and not clog the screen. The polyurethane is produced in tiles to allow for easy replacement of damaged segments without replacement of the entire screen section. The Two-Mass system allows for the entire screen to handle seven times as much force and capacity as competitive brute force machines.

Result

The increased capacity for the Two-Mass system and the durability of the polyurethane screen will be able to run the high capacity and abrasive material with ease and offered a better screening process that yielded increased product quality and consistency.

For more information on the STM-SCREEN™, talk to a GK Engineer today!