Is your facility ready for winter shutdowns? Every year, while many of us are relaxing and enjoying the holidays, scores of talented men and women are working hard to revamp and improve production lines. So if you haven’t had time to prepare yet, now’s the time. They’re coming up quickly!

For vibratory and rotary equipment, many parts are easy to replace and have short lead times, but others may require fabrication or longer order cycles. As part of the preparation for shutdown maintenance and for general good maintenance practices, here is a checklist of things you should review before your shutdown:

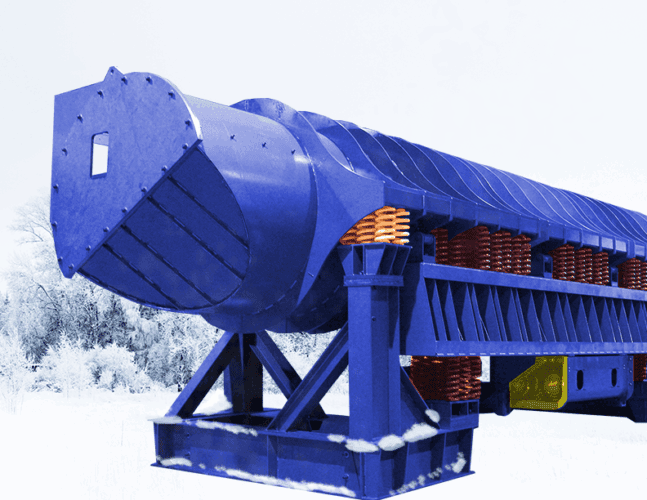

1.) Check the thickness and condition of trough/liners: Check the conveying surface of your machine. How does it look? If it is scored, cracked, or bent, it needs to be repaired. Use a thickness gauge or drill a small hole in the trough to measure the material’s thickness. If it is 75% or more worn down from the original thickness, it’s time to replace it.

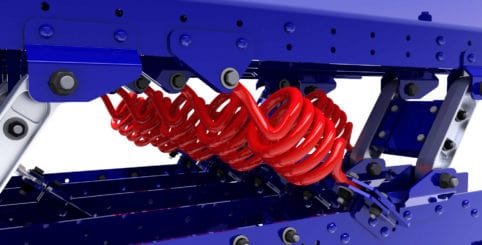

2.) Listen for noises: With General Kinematics equipment, if it’s running with no materials on it, it should be quiet. If you test the equipment and hear ticking or knocking from a rocker leg, that means it needs new bushings. If the drive is making noise, it’s probably time to replace your bearings. If springs are making noise, they’re broken, or the hardware is loose. Testing your equipment and listening to it regularly are great ways to catch problems early, before they get worse.

3.) Spare parts inventory: All GK equipment ships with a list of recommended spare parts. If your machine is in a critical process flow where an issue could result in the shutdown of your facility, you should have the necessary spare parts on hand to make repairs as quickly as possible. Take time to review your critical spare parts list with our GK customer service team to make sure you have the parts on hand to keep your facility up and running. If you don’t have a manual or parts list, contact us, and we can help you get them.

4.) Time for an upgrade: Is there a part of your process that doesn’t flow right? Do you want to improve efficiency or throughput in your system? Simple upgrades like drive conversions, trough reconfigurations, and liner upgrades can quickly restore or improve your system’s throughput.

The winter shutdown season is always hectic, so approaching it prepared is key. The GK parts and service team is available to help you review the equipment in your facility and develop an economical, efficient plan to breeze through the shutdown and deliver a well-running system back to your team. Give our team a call and schedule a free site visit to discuss how we can help you optimize your shutdown plans now before it’s too late. You can also register for the GK Parts Store to order critical spares online.