Ask the Experts

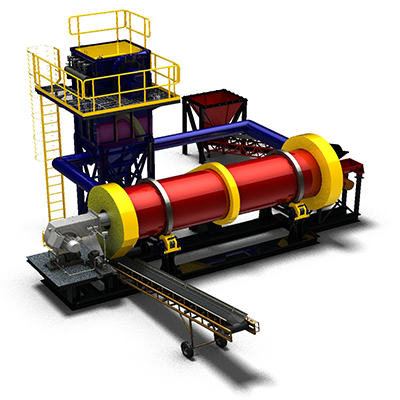

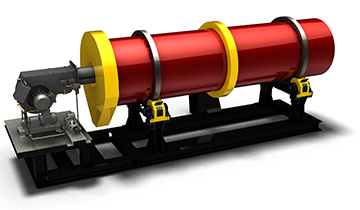

Rotary Dryers

Rotary dryers are used to remove unwanted water in organic materials to make them more usable. Rotary dryers lift the materials and pour it through heated air allowing the moisture to evaporate, which makes the organic materials viable. Although rotary dryers take regular wear and tear from these organic materials during the drying process, they are designed to withstand both high temperatures and abrasive materials.

GK ROTARY DRYERS:

Every General Kinematics Rotary Dryer is custom engineered to maximize the unique drying and processing needs of your material. GK Rotary Dryers use rotary motion to lift and cascade your material through the hot gas stream, evaporating moisture evenly. Dryers can be designed using various drying technologies, and when working with us, you can pick the technology that best fits your needs. Choose between direct drying in counter-current or co-current flow, or indirect drying, which utilizes ing external heat applied to the exterior of the drum shell.

General Kinematics offers rotary dryers that are able to process a wide variety of materials, including:

- Aggregate

- Agricultural products

- Biomass materials

- Fertilizer

- Gypsum

- Limestone

- Municipal waste

- Sand

- Wood and organic fibers

GK ROTARY DRYER BENEFITS:

GK rotary dryers are built to last, and may also help you reduce your maintenance costs. That’s because our designs use extra heavy-duty components for extended uptime and minimized upkeep. Not only that, but material contact surfaces are manufactured from wear-resistant materials, so drums will last a long time between servicing. Rotary trunnions and rings are forged for superior strength and durability and are easy to replace or resurface.

Let the engineers at GK work with you to design a complete drying system that meets your needs. Couple your rotary dryer with GK’s proven vibratory material handling equipment to pre-process, feed, and deliver your dried product to the next step in your manufacturing process.

Rotary Dryer Features:

- Rotary Dryers internal flighting and lifting sections customized for your application.

- Direct drying available in counter-current or co-current flow designs.

- Dryers can be designed to use various readily available fuel sources.

- Available with auxiliary vibratory in-feed and take away conveyors.

Learn More

To learn more about General Kinematics rotary dryers and equipment, simply fill out the form below to get started today. Since our rotary dryers are build-to-order, we’re here to help you figure out what type best meets your needs.