The principles of two-mass technology are simple enough. Rather than relying on drives alone to create the necessary vibration, these designs power the feeder with a clever distribution system. It’s a concept that can save your workforce unneeded labor and your organization unneeded loss. Let’s see how-

Reliable Design

Brute force feeders suffer enormous strain. The pressure put on their components creates a hostile environment of irresistible friction and shock. In consequence, it isn’t long before the machine’s own forces begin working against it. Snapped belts, unaligned surfaces, and damaged machine parts are relatively frequent. That can only spell expensive delays and repairs.

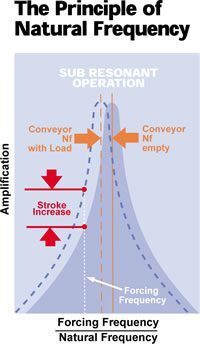

Two-mass machines cushion the entire process by redistributing the energy. Rather than relying on the motors to do all the lifting, a regulating spring system is placed between motor and trough. This balances the forces and provides more consistent angles for the trough feed.

When you opt for two-mass technology, the bottom line is less wear and tear, increased productivity, and fewer hold ups.

More Efficient Workflow

Because the spring systems are in place between the exciter and assembly in two-mass technology, their natural elasticity can exploited. The coil vibrates very efficiently with power consumption significantly below brute force standards. That’s how two-mass designs can cut horsepower by over 60% while giving comparable performance.

But the even greater cost advantages are those found in the materials being handled. Two-mass technology separates and conveys more efficiently by transmitting more energy into the materials being worked. For instance, General Kinematics two-mass feeders used before optical sorters see 5-10% greater recovery than traditional brute force feeders.

Easy Maintenance

Two-mass machines have modest motors and require no belts, couplings, or bearings. That means you reap significant repair savings.

No more redundant parts to keep on hand. No more specialist training for workers to maintain the feeders. No more interruptions when obscure tools and equipment can’t be procured. Two-mass technology is practically foolproof- just set it up, plug it in, and let production happen.

Putting Two-Mass to Work for You

We hope you’re excited by the labor and energy saving possibilities of our designs. Whether you’re thoroughly convinced or have more questions, please don’t hesitate to set up a consultation with our accomplished team of engineers. Working together, we’ll set a new standard for your company’s productivity and profits!