Without the mining industry, your Smartphone would not be so smart. In fact, the majority of all electronic devices make use of more than 35 minerals. Some of these important minerals include silver and gold. Without mining, baking soda would not be available for cooking and cleaning. In addition:

- The average computer uses more than 30 minerals for operation.

- The state of Colorado accounts for the biggest titanium resource in the United States. Titanium is used in jet engines, aircraft frames, jewelry and many more products.

- Surface mines in the U.S. account for 85% of minerals extracted and 98% of metallic ores.

- In 2011, Mexico produced the largest amount of silver at 152.8 million ounces.

- The U.S. is the second largest producer of coal and third largest producer of gold. China is the largest producer of gold.

- Close to 500,000 people are employed in mining in the U.S. alone. Another 2 million are employed in support operations in the U.S.

- Evidence of mining activities date back almost 43,000 years.

Surface mining:

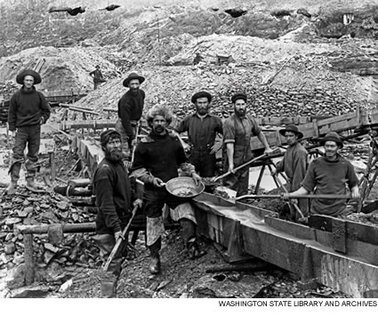

Surface mining variations include hydraulic, open pit, dredging, mountaintop removal, strip and placer techniques. Placer mining is used where minerals are found in gravel or sand. Gold panning is a form of placer mining.

Underground mining:

Variations in underground work include slope, drift, borehole, shaft and hard rock. Drift mines use horizontal entries through a hillside. Shaft mines use a vertical entrance and slope mines enter at an angle between horizontal and vertical.

Coal mining efficiency can be greatly improved with the use of mobile units. This equipment provides quicker set up and reduces costs associated with set up time and maintenance. Conveyors can process the coal while it is being transported offering additional savings for the industry.

The need for dangerous chemicals, including arsenic, is greatly reduced with the use of leaching mining equipment. This is better for the environment and reduces costs. Mining machines are becoming more efficient and safer for both operators and the environment. Modern methods include reclaiming and repairing damage from surface and underground operations.

Mining is a global industry. Very few countries do not participate in some form of mining operations. The mining industry employs laborers, supervisors, engineers, mechanics and many other skilled and unskilled workers. The demand for minerals will continue and as it does, the industry will continue to improve the technology used for efficient and safe operation.