Foundries today are under immense pressure to deliver more with less—less energy, less waste, and fewer delays. However, bottlenecks in production often hinder operational excellence. At General Kinematics, we specialize in identifying these choke points and providing smart, efficient equipment solutions that eliminate them.

Here are five of the most common bottlenecks foundries face—and how GK equipment is designed to solve them.

VIBRA-MILL® Sand Reclamation System

1. Inefficient Sand Handling and Reclamation

The Bottleneck: Manual waste sand handling and ineffective reclamation increase material costs and reduce cycle efficiency.

GK Solution: Our VIBRA-MILL® Sand Reclamation Systems streamline sand recovery with minimal operator input. These systems break down, cool, and screen used sand, reducing waste and cutting down on fresh sand requirements.

SPIRA-COOL® Casting Cooling Conveyor

2. Cooling Time Delays

The Bottleneck: Traditional cooling methods often require excessive floor space, air handling equipment, and time, creating delays in downstream processes.

GK Solution: SPIRA-COOL® Casting Cooling Conveyors combine cooling and conveying in a single step. Custom designed to your process, each vibratory SPIRA-COOL® can replace over 400 feet of vibrating casting cooling conveyors in a single, small footprint while elevating your castings for further sorting or shot blast operations.

General Kinematics’ New Patented Duro-Spring™ Drive System

3. Excessive Maintenance / Downtime

The Bottleneck: Frequent maintenance interrupts production schedules and drives up operational costs.

GK Solution: GK’s Two-Mass Vibratory Equipment is engineered for low maintenance and high durability. Two-Mass equipment uses up to 2/3rds less energy, extends component life, and reduces unplanned downtime. Learn more about GK Two-Mass technology here.

General Kinematics vibratory sorting conveyor conveying castings

4. Poor Material Flow and Segregation

The Bottleneck: Inconsistent material flow and segregation during transport can lead to product defects and quality control issues.

GK Solution: GK feeders and conveyors ensure a consistent, controlled flow of bulk materials. Our variable frequency drives and custom-engineered solutions minimize segregation and improve overall quality.

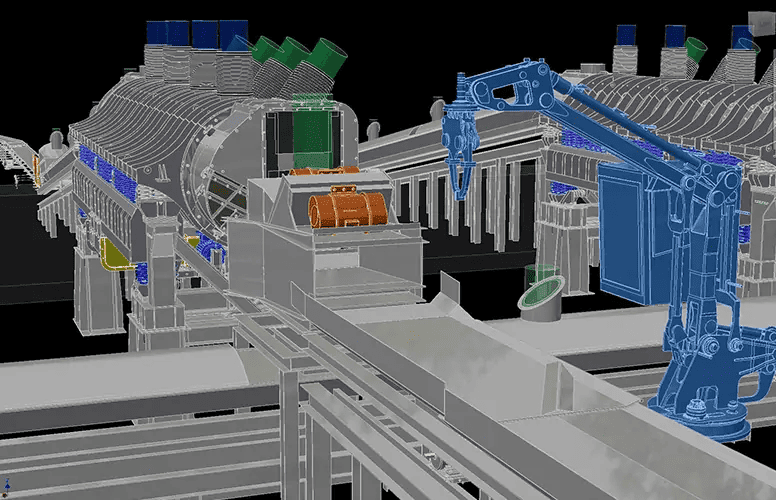

GK Casting Processing Lines

5. Lack of Integrated System Design

The Bottleneck: Foundries using piecemeal equipment often face inefficiencies due to poor integration.

GK Solution: GK Systems offers turnkey foundry systems designed for seamless integration. From material handling to casting cooling, every component is engineered to work in harmony, maximizing throughput and efficiency.

Final Thought

Every foundry is different, but bottlenecks are universal. With over six decades of experience, General Kinematics delivers equipment and systems that not only remove barriers but set new benchmarks in foundry efficiency. Our commitment extends beyond just selling equipment; we partner with our clients to understand their unique challenges and co-create tailored solutions that deliver measurable results. From initial consultation through installation and support, GK and GK Systems are invested in your long-term success. Whether you’re modernizing an existing line or building a new facility from the ground up, we’re here to make sure your operation runs smarter, safer, and more profitably. Ready to optimize your operation? Let’s talk.