For many companies, manufacturing equipment is a significant investment. However, properly selecting, assembling, and maintaining your equipment can improve process efficiency in such a way that the original equipment investment is recouped multiple times over.

Not convinced? Let us show you the ways that General Kinematics can help you reduce manufacturing and equipment costs and keep your machinery working effectively over a long equipment lifetime.

Integrate With Automation

If you’re looking to improve the efficiency of your process, the automation of manual processes and the improvement of slow processes (aka, bottlenecks) are good places to start. GK offers a wide variety of vibratory, rotary, and process systems equipment that can help streamline your processes and solve your most difficult processing challenges.

Specializing in the processing of bulk solids, we work with you to build custom solutions for automating manual processes or simplifying overly complex processes – reducing processing time and thus reducing manufacturing costs. Even if your equipment needs seem straightforward, working with GK to choose the equipment that is right for your process ensures that the improvement will be worth your investment.

Assembled With Excellence

A long equipment lifespan begins with proper assembly and installation. Therefore, although using in-house resources to install your equipment may save money in the short term, it is always best to have an expert GK professional perform the installation and troubleshoot any issues that may arise.

If a piece of equipment is not properly assembled or installed, the equipment may malfunction or ruin efficiency during regular operations. A constant need to fix these issues can be costly in the long term and lead to significant downtime.

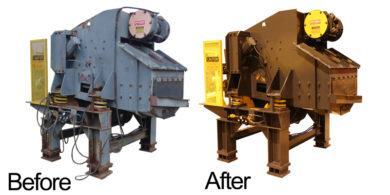

Reducing Costs with Equipment Rebuilds

A fabrication, or rebuild, is the process by which used equipment is rejuvenated to improve its life expectancy. Small repairs may seem like an easy way to save money, however quite often we see customers make small repairs that snowball into a large amount of damage. For any amount modification, it is important to contact the manufacturer to ensure this doesn’t happen to you. Larger issues or full rebuilds should always be performed by qualified vibratory equipment professionals to ensure the right solutions are found.

For a rebuild, the equipment is sent back to the GK shop for repairs or maintenance. The nature of a rebuild varies depending on the condition of the equipment and the materials it processes. Regardless of those factors, rebuilding can increase uptime and extend the life of your equipment (and thus increase your return on investment). In many cases, old equipment can run like new after a rebuild.

Depending on how well your equipment is maintained, a rebuild can extend the life of your equipment up to 80%. Therefore, because a rebuild typically costs around half the price of a new piece of equipment, a rebuild can significantly decrease the amount you have to spend to keep your process up and running.

The General Kinematics Commitment

At GK, we are committed to our customers over the entire lifespan of their equipment, from equipment selection and customization to repairs and rebuilds. To find out more about how General Kinematics lives by this commitment, contact us today.