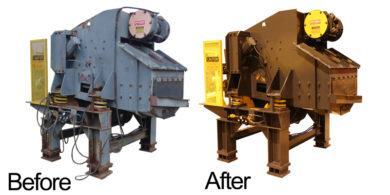

Rebuilding your existing equipment can increase uptime and return on your initial investment. However, the work is different depending on the current state of the machine as well as the type of materials the unit has run. Another nuance is the quality of care the machine is typically given. These differences create unique challenges for the rebuilder. This is why it is important to trust rebuild work with the original builders.

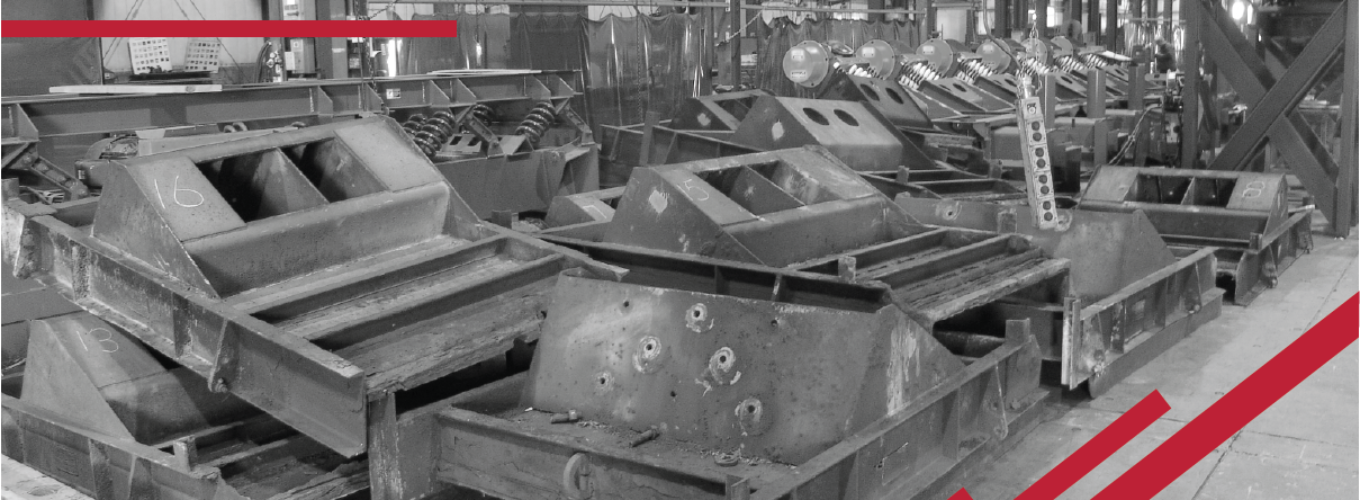

General Kinematics knows vibratory equipment from the inside out. Our team of engineers and craftsmen have the skills and expertise to rebuild equipment in any shape and order. We understand that many customers like to rebuild equipment to save money. This is why when rebuilding equipment we incorporate as much of the original structure as possible without jeopardizing the unit and extending the life of your newly upgraded machine.

Reinvesting in your equipment can expand the life of your unit up to 80%, depending on how well it is maintained, run, and the environment in which it operates. This can mean huge cost savings as unit rebuilds average 50% of the initial cost of your equipment. That is a 30% return on your original investment if done correctly.

When it comes to choosing a manufacturer to rebuild your unit, it is smart to work with someone you trust, who has a breadth of engineering knowledge to ensure that rebuild will not impact the effectiveness of your equipment and ultimately leave you spending even more. It is also important to choose a company you trust to stand by their work and offer assistance when needed.

General Kinematics has been engineering vibratory equipment for more than half a century, catering to a multitude of industries and ever-evolving product varieties. With a proven track record of customer support and expert solutions, your refurb process is in good hands with GK. Talk to a GK engineer today to get your old unit running like new!