When it comes to curbside recycling, there are three types of people: those who recycle; those who don’t recycle, and those who recycle correctly.

The growth of commingled (single-stream) recycling—where all recyclable products are placed in a single container for curbside pickup—has dramatically increased the rate of recycling by as much as 50 percent in communities across the U.S. However, because it is so easy to throw items to be recycled into a single large bin, recyclers are finding that more of the material is either contaminated or not recyclable.

China, the world’s largest importer and recycler of scrap metals, plastic, and paper, has decided it will no longer take what it calls “foreign garbage” and, through its Green Fence policy, has banned the import of 24 types of waste. Entire shipments of recycled products are being rejected if contamination is found. This is putting enormous pressure on the waste collection industry to develop more efficient sorting methods and more recycling plants.

General Kinematics has responded by continuing to work with our customers to leverage the advanced vibratory recycling equipment in municipal solid waste sorting solutions that automate the process of efficiently separating recyclable materials.

How to Recycle

A major problem for the waste collection industry is the improper disposal of contaminated and non-recyclable materials in the curbside recycling container. Recycling instruction labels are now attached to the lids of single-stream containers and waste collection companies are publishing flyers for direct mail and posting infographics on social media sites to educate homeowners and businesses on what type of materials can be recycled and the preparation of that material for recycling.

Food contamination is one of the biggest problems in the recycling industry. That glass spaghetti sauce jar is recyclable, and so is the aluminum lid, but only if all the remnant sauce is thoroughly rinsed from the container. Pizza boxes and fast food wrappers, even though they are made of paper or cardboard, cannot be recycled because of the grease.

Another recycling problem is products made with two different materials, such as milk cartons made of cardboard with a wax coating or boxes with an aluminum foil lining. These types of materials cannot be recycled.

Plastic wrap and grocery bags can, in theory, be recycled but cannot be placed in the curbside recycling bin. The material is too thin to be processed effectively through the equipment in a traditional municipal solid waste plant. If you can poke your finger through the plastic, it cannot be recycled. Most grocery stores have a collection container where customers can bring back their plastic grocery bags to be sent to a special recycling facility. Styrofoam is another plastic that cannot be recycled.

Products to be recycled must be clean, dry and loose in the recycle container. They cannot be placed in a plastic bag.

Recycling in the U.S. vs. Europe

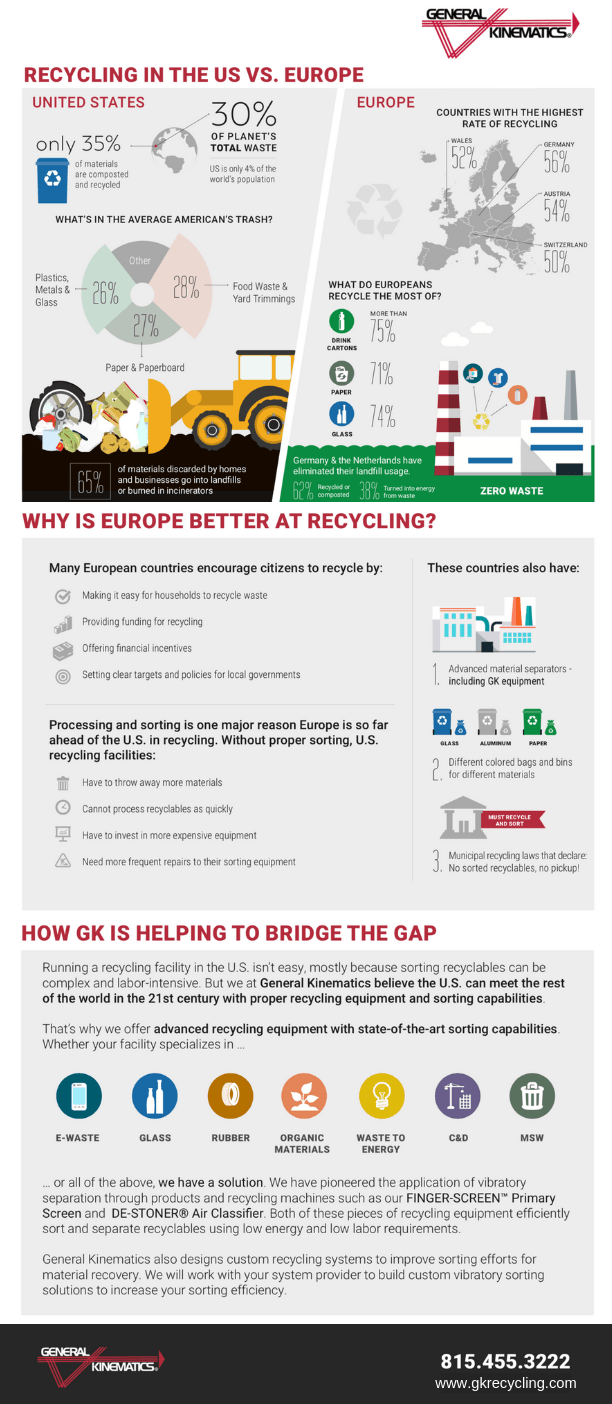

The United States makes up only 4 percent of the world’s population, yet it produces 35 percent of the planet’s total waste. Despite the dramatic increase in curbside recycling, the U.S. only recycles and composts about 34.6 percent of its material waste. The average American’s trash contains 26 percent plastics, metals and glass; 27 percent paper and paperboard; 28 percent food waste and yard trimmings.

Contrast the U.S. recycling rate with that of European countries and you will see a dramatic difference. Both Germany and the Netherlands have completely eliminated their landfill usage by recycling or composting 62 percent of their waste. The remaining 38 percent is turned into energy from waste. In the European Union, 74 percent of glass containers, 71 percent of all paper and 76 percent of beverage cartons are recycled.

Countries with the highest rate of recycling are Germany at 56 percent; Austria 54 percent; Wales 52 percent and Switzerland at 50 percent.

Why is Europe better at recycling?

Many European countries encourage citizens to recycle by providing strong financial incentives. In Switzerland, for instance, recycling is free, but in most parts of Switzerland throwing away rubbish costs money. Each rubbish bag has to have a sticker on it and each sticker costs at least one euro. So, the less you throw out, the less you pay. No sticker? Then the rubbish will be left outside your house to rot.

Convenience is another factor. In Switzerland, there are bottle banks at every supermarket, with separate slots for clear, green and brown glass. Every town has a free paper collection once a month and that does not mean just old newspapers. Most people recycle everything made of cardboard or paper, from cereal packets to old telephone bills. There is also green and organic waste. If you have a garden, all the trimmings can be put out on the street (neatly bundled of course) every two weeks and they will be collected.

In Germany, there are at least four types of rubbish bins in the courtyards of apartment buildings and inside people’s houses. The bins are color-coded to avoid any confusion — a yellow bin for packaging (old milk cartons, etc.); a blue bin for paper and cardboard; bins for glass (usually with individual spots for clear, brown and green glass), a bio-bin designed for leftover food and plant waste. Finally, there is a black bin for the rest of the rubbish (or for those people who do not bother to sort out their rubbish). In addition, many European governments set clear target and policies, backed by funding for recycling programs.

Meanwhile, in the U.S., the inclusion of non-recyclable and contaminated materials into the recycling stream causes recycling facilities to have to throw away more materials and dramatically slows down the sorting process. Plastic bags and other materials cause sorting equipment to jam and require more frequent repairs.

The future of recycling in the U.S.

It is clear that the U.S. needs to provide more financial incentives and education for the public to encourage source separation. Recyclers will then be better able need to turn these resources into usable products.

The industry leaders at General Kinematics continue to work with waste and recycling companies to build better and faster equipment, such as DE-STONER® Air Classifiers for municipal solid waste. This equipment can separate and sort waste more efficiently. It uses air instead of water to remove heavy product from light product, eliminating the mess and environmental hazards water separation creates. The machine’s design makes it virtually jam-proof with no moving separator parts, and its versatile design separates material of different density or equal densities with varying particle size.

General Kinematics is also working with leading WTE plants around the world to continue to develop products such as the FINGER-SCREEN™ for Waste to Energy and Vibratory Fluid Bed Dryers. For more information on General Kinematics resource recovery, recycling and waste to energy equipment, contact one of our six offices in the U.S., Germany, England, Beijing, Shanghai or India.