Brute force vibrating screens have been a staple in the mining industry for about as long as there has been a mining industry. The easiest way to separate this bulky material is through movement dividing the material based on size. Brute force screens have long been an economical way of accomplishing this. However, as raw feed continues to decrease in concentration, mines have had to supersize their processes in order to create enough quality material. As these throughput requirements grow, so has the size of the equipment needed to process the increased quantities.

As more mega plants come online, and brute force screens have had to get larger, the force required to shake these machines has reached a literal breaking point. While screen sizes continue to expand, the structure has to be lightened in order to have enough horsepower available to handle the process. So much force is needed to shake a large brute force screen that this lightened physical structure no longer holds together. We hear about the same issues every day, regardless of the screen manufacturer: Structures continue to break after a short period of time due to the extreme stress concentrations around the drive system. Once broken, they can only be repaired so much before the screen has to be removed and replaced. This replacement event is happening between 6 months and 2 years for most large screens at mines around the world.

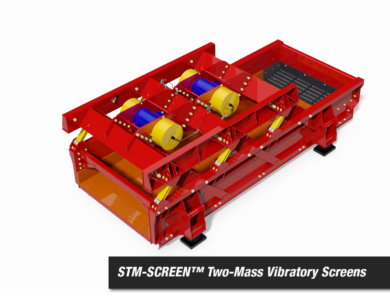

General Kinematics engineers have studied the issues of traditional brute force screens, working with miners around the world to create the answer to their downtime headaches utilizing our proven Two-Mass technology. The GK STM-Series™ Vibrating Screens utilize an integrated spring system between the drive and the screen body that evenly spreads the load along the length of the structure. By doing this, forces at any particular spot are kept to a minimum, significantly reducing stress fatigue.

This spring system has the additional benefit of amplifying the vibration using up to 2/3rds less horsepower. The reduction in horsepower allows for a significantly stronger physical machine structure, creates a screen that has a greater recovery rate and can be much larger than brute force screens.

When determining the return on investment, customers who have committed to the STM-SCREEN™ with its higher initial price have seen faster payback with much less downtime and a much longer equipment life.

Interested? Contact GK’s mining team to have them show you how quickly you can turn your investment in a GK STM vibrating screen into a significant increase in throughput and mine profit.