The “Quick Fix” That Isn’t

In mining and aggregate operations, equipment reliability isn’t a “nice-to-have”; it’s everything. When your screen fails, production stops, and downtime costs pile up.

That’s why some screen suppliers push dynamic bases as a solution to reduce structural vibration in brute force screens. On paper, it sounds good: add a second frame and a new set of springs, and vibration magically disappears.

But here’s the truth: dynamic bases are an expensive band-aid that doesn’t solve the core problem.

Why Dynamic Bases Fail in the Real World

A dynamic base can reduce some steady-state vibration, but things change the moment the machine ramps down. As the screen coasts through its natural frequency, the system hits resonance. The result? Violent oscillation and “bouncing” that drives shock loads back into your structure.

In fact, shutdown forces with dynamic bases are often 10–20x greater than normal operation, and 2–3x higher than running the machine without a dynamic base at all. That means more fatigue, more structural cracking, and more maintenance headaches.

On top of that, adding a second set of springs creates multiple resonant frequencies. When those overlap during shutdown, the vibration problem gets worse, not better. And every added component means more cost, more complexity, and more points of failure.

The Questions You Should Be Asking

Before signing off on any screen purchase, ask your supplier for:

- Load data without the dynamic base

- Load data with the dynamic base

- Shutdown cycle load data (the real test of reliability)

Most vendors won’t share this information because the numbers don’t look good.

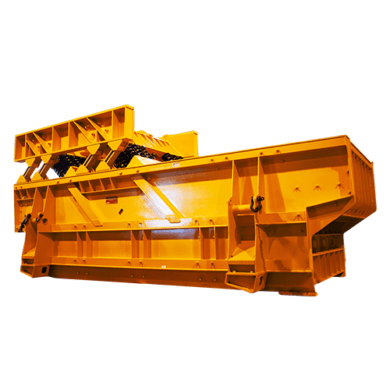

The Better Way: STM-SCREEN™ by General Kinematics

Instead of trying to mask brute force vibration with complex add-ons, GK engineered the STM-SCREEN™ Two-Mass Vibratory Screen to eliminate the problem at its source.

- Two-Mass Natural Frequency Design – Absorbs and redistributes energy, dramatically reducing transmitted forces to your structure. No need for “extra bases” or shock absorbers.

- Low Shutdown Forces – Smooth, controlled transitions through startup and shutdown cycles without resonance spikes.

- Long-Term Reliability – Fewer structural failures, fewer emergency repairs, and more uptime.

- Lower Total Cost of Ownership – Less steel, less maintenance, and a design that lasts decades instead of just a few years.

The STM-SCREEN™ isn’t a patch; it’s a proven, engineered solution trusted by mines around the world to run 24/7, year after year.

The Bottom Line

Dynamic bases might look like a fix on a spec sheet, but in real operations, they add cost, complexity, and risk without solving the real problem.

That’s why the only logical choice for high-capacity screening is the GK STM-SCREEN™. It’s the screen designed for your operation, not just for the brochure.

Ready to upgrade your screening reliability?

Contact GK today: info@generalkinematics.com