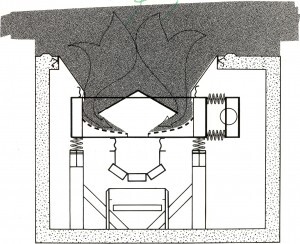

The construction of the UN-COALER® activator/feeder consists of a square or rectangular box structure with two symmetrical “feeder” pans in combination with a center dome.

The geometry of the material flow path is similar to the requirements for open pan feeders. The center dome is part of the box structure and functions as a pile activator or vibrating hopper bottom which produces a vibratory action to the material to reduce arching and induce the flow from the storage pile.

The entire assembly is vibrated horizontally by the natural frequency drive mechanism identical in design to a coil spring feeder drive.

The bottom slot opening feeds the material to the belt to deposit the bulk material symmetrically and centrally to develop an ideal belt loading situation. Sealing is simple and complete with installation of seals.

Rectangular shapes allows simple hopper design without the need for an expensive circular transition piece between hopper and activator. UN-COALER® mounts on a separate support.

An arch breaker mounted above the material feeding troughs is designed to transmit vibrating forces into the storage pile without compacting the material.

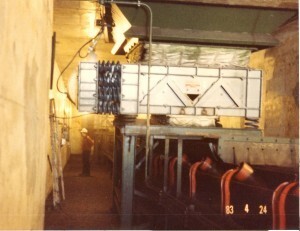

Each UN-COALER® is foot mounted on isolation springs thus the tunnel roof does not have to be designed to withstand the weight of the unit or any dynamic forces. Automated control systems arranged to respond to belt scale, load cell, or computer signals, allow individual or multiple unit control of the UN-COALER® for selective reclaiming from virtually any point or combination of points along the tunnel.

The low profile design of the UN-COALER® reduces the cost of foundation excavation since the tunnel does not have to be as deep. Straight-line surfaces eliminate elaborate concrete forming. The few moving mechanical parts of the UN-COALER® are easily accessible from the tunnel to minimize maintenance procedures.

Advantages

- Large vibrating openings, up to 12 x 12 inch, permit large hopper discharge openings for greater drawdown volume.

- Compact, low profile design reduces tunnel depth for a substantial savings in foundation cost.

- Fixed or variable feed rate design permits continuous operation to assure uniform feed to reclaim conveyor.

- Unit mounts directly above belt conveyor and evenly distributes material to eliminate belt tracking problems.

- Few moving mechanical parts are easily maintained from the tunnel.

- The entire UN-COALER® is mounted below grade.

- Rectangular shape with straight-line surfaces greatly simplify hopper design, dust and connections, and concrete work.