CONVEYORS DESIGNED FOR ANY MATERIAL YOU THROW AT THEM.

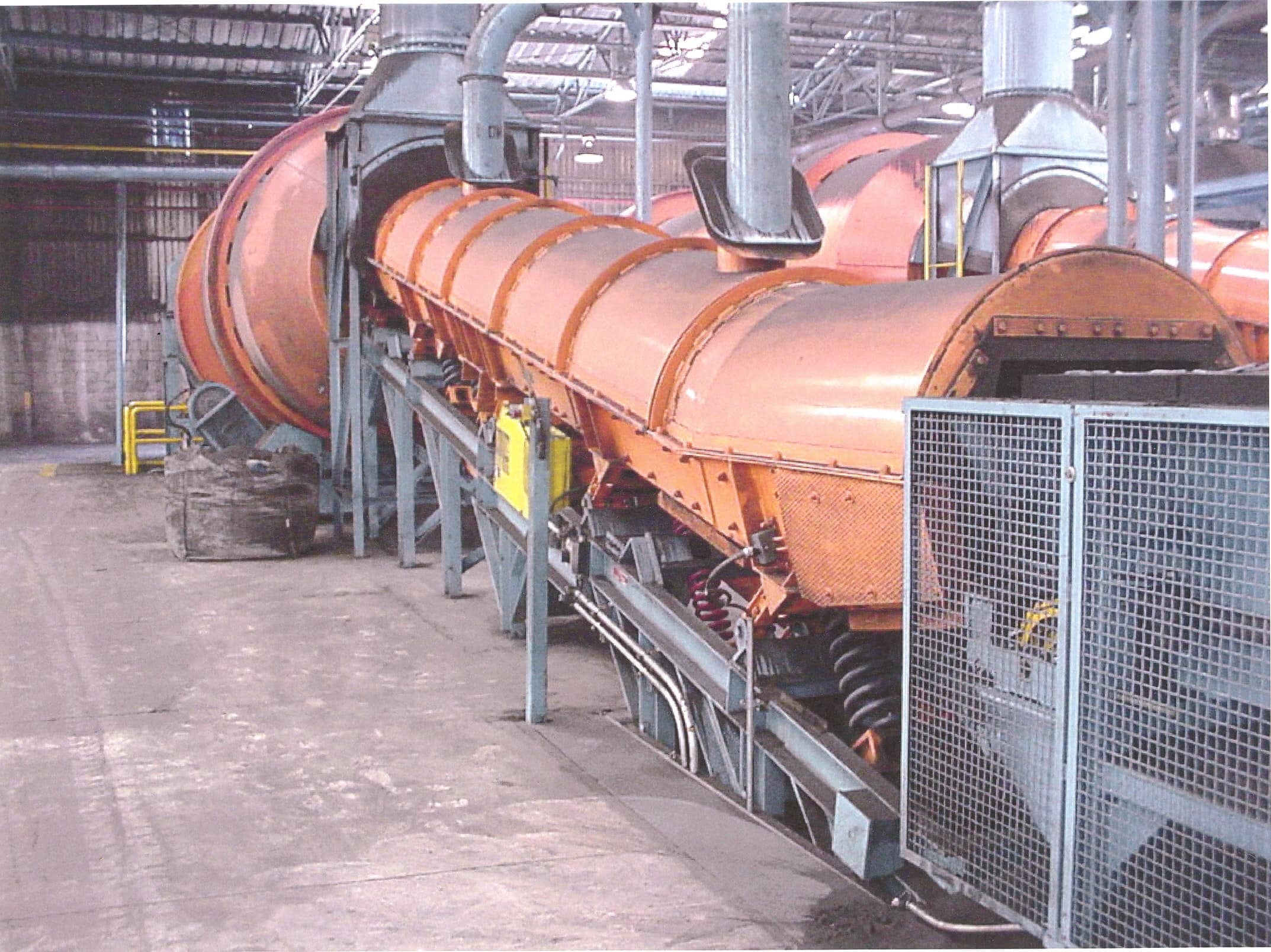

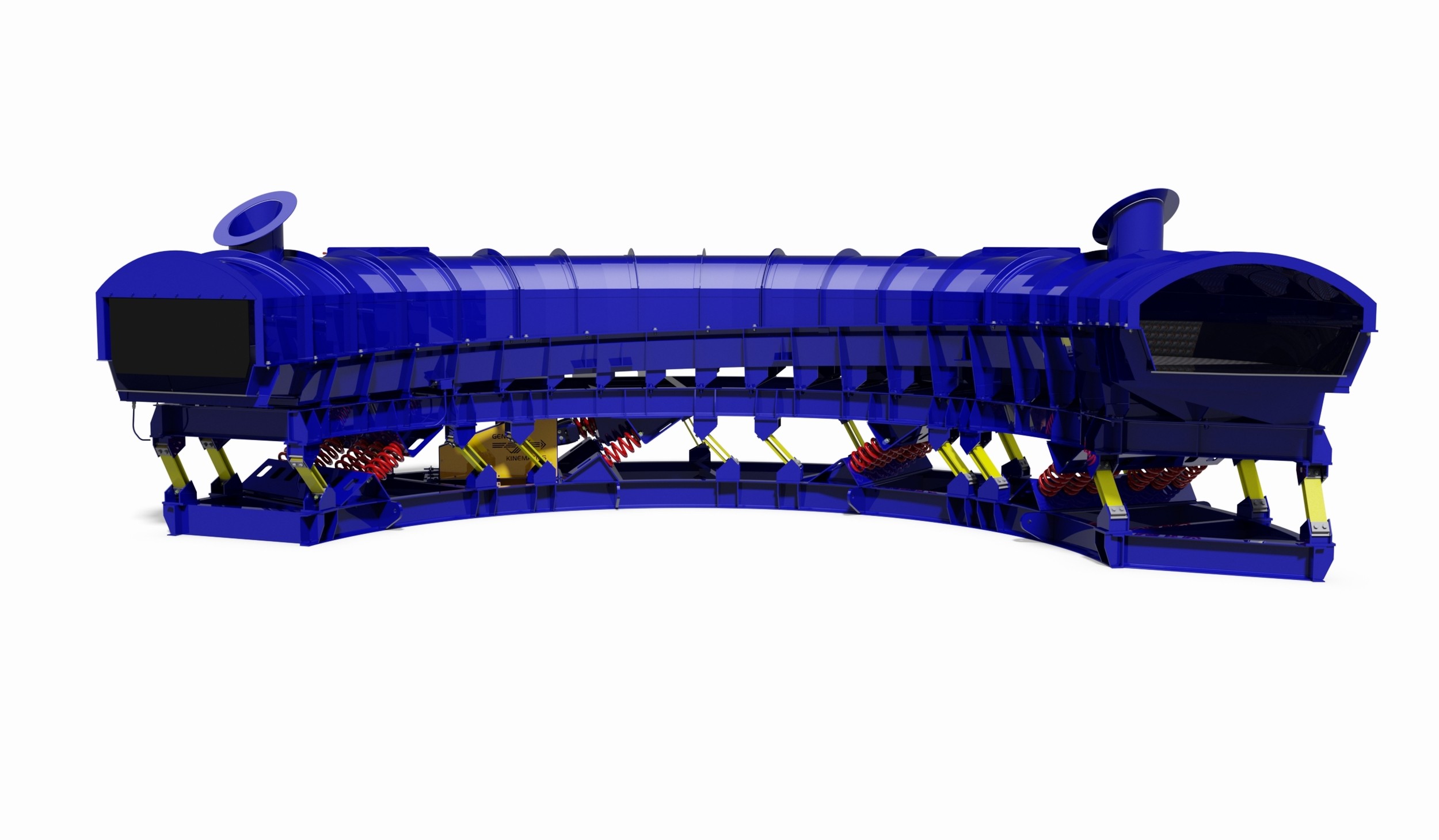

Would you push a glowing red casting onto a rubber belt? No. How about hot flowing sand onto an apron or metal belt conveyor? Only if you like to sweep. Only one technology meets the demanding environment of a hot and abrasive foundry, and that is vibratory conveyors from General Kinematics. General Kinematic conveyors are made to handle large volumes of a variety of bulk materials. Use to feed, screen, scalp, separate, blend, cool, dry, grade, or spread while conveying, from sand to casting.

MORE THAN JUST CONVEYING

Versatile vibratory conveyors from General Kinematics do more than just move materials. The inherent motion of continuously tossing and throwing material forward creates the opportunity to perform one or more processes along the way. Depending upon your application, conveyors can be engineered and constructed with custom trough designs to handle hot, heavy, and/or abrasive materials in the foundry, including sand, sprue, castings, and dross. Conveyors can be constructed using a variety of materials, including mild or abrasion-resistant steel, stainless steel, or special alloys. Special patterns, perforations, and trough thickness can also be specified to meet your application needs. Customize your conveyor to efficiently meet industry standards, company processes, or to control feed rates for your product.