Unfortunately, operations at foundries are capable of eating up high amounts of energy. Not only does such energy consumption prove costly over time, it does nothing for the state of the environment. If you’re hoping to minimize energy expenses while doing your part for Mother Nature, consider implementing one or more of the following energy saving suggestions:

Regenerative Drives

The regenerative drive offers foundries an excellent opportunity for recapturing energy. Essentially, this technology captures a mechanical energy output and converts it into electricity. In this way, a portion of the energy being used in various processes at the foundry can be recaptured and used to create even more energy.

High Efficiency Burners

Anneal ovens are a huge source of energy expenditures for a number of foundry operations. Annealling is a necessary part of a foundry’s work, so some energy usage will always be required for this step. However, with the use of high efficiency anneal oven burners, energy consumption can be cut to a fraction of its current levels. Again, the regenerative process is key in this effort.

Low Horsepower Equipment

There is a lot of machinery required to move all the materials throughout an automated foundry operation. Proper equipment selection can significantly decrease the amount of horsepower and energy required to move these materials. When it comes to vibratory equipment in your operation, utilize equipment designed with two-mass drive systems . Two-mass vibratory equipment requires up to two-thirds less energy when compared to vibratory machines where the motors are bolted right to the body of the machine.

Machine Automation

Leaving equipment run all day is not only inefficient, but can lead to premature wear of components and machinery. Automating machinery through control technology allows machines to be activated only when required by the upstream material flow. Weigh cells, photo eyes, and other detection methods can be used to determine if the machine is loaded or not and operate it accordingly. Automated controls can also detect when a machine is operating out of specification and warn operators before a bigger problem occurs.

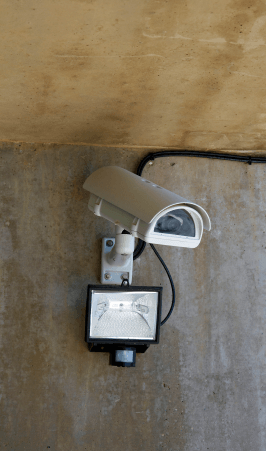

Sensored Lighting

Some portions of foundries see far more foot traffic than others, yet, in many operations, the entire workplace remains lit throughout the entire day. Why light an area if it is not being in any way utilized by foundry employees? Sensored lighting can be highly valuable in this regarding, picking up motion signals of approaching workers and turning on lights immediately prior to their arrival.

Renewable Energy

While regenerative drives offer an excellent means to recapture energy, there are plenty of other ways to create energy without burning mass amounts of fossil fuels. One idea: work renewable energy into your foundry’s operations. If you live in a sunny climate, you may want to consider adding solar cells to your roof. Foundry workers easily have the skills to set up solar panels, so the only true cost involved is that of materials — and in a short time, the materials used to bill solar panels will pay for themselves.

It’s not hard to reduce energy output or obtain energy from renewable resources — it simply may require a little thinking outside the office. But that creativity and effort will be worthwhile, dramatically reducing both energy costs and your carbon footprint.