Fracing, also known as fracking, hydrofracking, or hydraulic fracturing, is a process used to “fracture” the rocks beneath earth’s surface (hence the name – fracing) in order to extract gas or oils. The process involves injecting a high-pressure fracking liquid (usually water, with some additives) into the ground, forcing the gas and oil out of the fractures where it can be pulled to the surface through pipes.

Fracing has its roots in the civil war era, where the original method of extracting crude oil and natural gas involved a variety of explosives used to create the necessary fractures. This process was complicated and dangerous – leading to the development of hydraulic fracing in the 1940s, and continued improvements on the process since. Due to high oil prices and recent improvements in the technology, fracing is becoming more widely used and, in turn, more widely scrutinized.

The Process

While the original process of fracing was the equivalent of exploding a torpedo underground, the method of fracing has changed immensely over the last century and a half. It’s become much more scientific, intentional, and not to mention: safe.

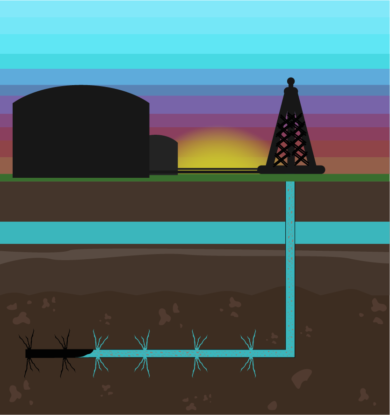

Today, hydraulic fracing starts by drilling horizontal wells into the ground. These wells are then injected with a combination of water, sand (known as frac sand), and chemicals that fracture rocks under the earth’s surface, releasing the hydrocarbons used in oils and gas.

Fracing Controversies

Because of the fracturing that happens, the industry term for this process is “fracing”, like a shortened version of “fracturing”. However, the media spells it out as you pronounce it – “fracking” – so it’s likely you’ve read it that way before.

The spelling of the word isn’t the only controversy surrounding fracing, though.

Due to high oil prices and recent improvements in the technology, fracing is becoming more widely used and, in turn, more widely scrutinized. Anything affecting our natural resources is bound to spark such controversy, and there are valid points to both sides.

The Benefits

The benefits to fracing are mostly economic, offering more jobs, lowering gas and oil prices, increasing our reserves, and reducing our dependence on other countries. There are however a few ecological benefits as well. Burning gas produces less contamination in the air than burning coal and with more gas in the reserve, our air quality will improve. One more major plus is that with this excess reserve the industry is given more time to find methods of renewable clean energy.

The Concerns

The main concern in fracing is water pollution. As water and chemicals are a major part of this process many are concerned about the water seeping through the ground to drinking water sources. Coupled with this concern is the amount of water that is lost in the process. One of the most publicized issues, due to its noticeable effects, related to fracing is the tendency to cause earthquakes. Many residents in areas with high fracing are concerned with the new seismic activity.

The Future

Many researchers in the fracing industry are working to reduce the negative impact on the environment and improve their process. General Kinematics is joining the effort to improve this with better processing equipment. From fluid bed dryers to sand classifiers, GK has a variety of vibratory solutions to improve the processing of frac sand.

Contact us to see what GK can do to improve your fracing process!