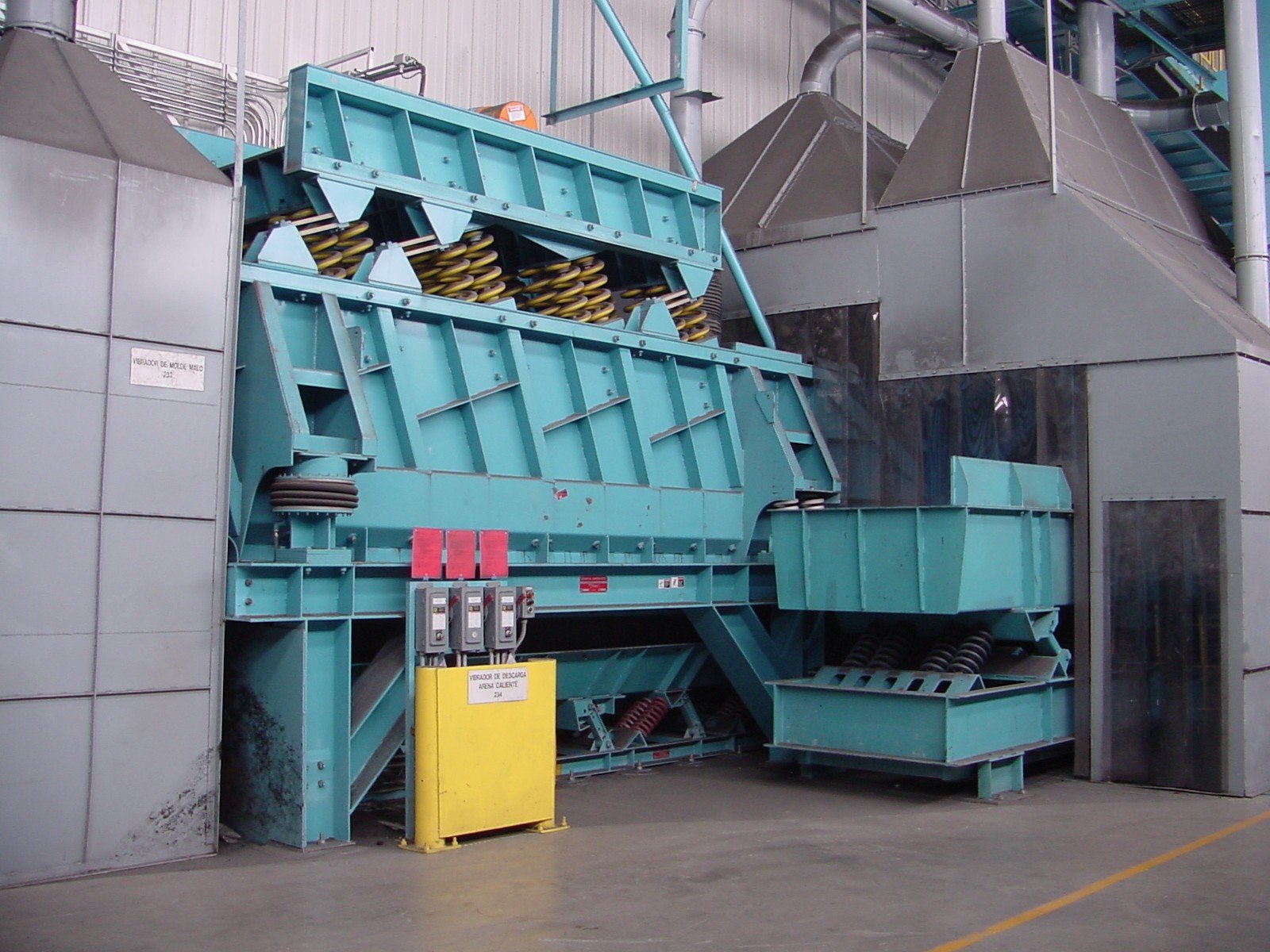

General Kinematics Two-Mass, High Frequency shakeouts boost foundry throughput. Our simple two-mass shakeouts automatically compensate for varying load conditions, assuring full, non-dampening performance. Driven with sealed vibratory motors, GK’s Two-Mass shakeouts eliminate the need for V-belts, pivoted motor bases, couplings, and large and expensive bearings. Drive is mounted on a separate exciter mass, completely isolated from the high intensity impact action of the shakeout deck.

Using a two-mass natural frequency spring system between the drive and the shakeout body, two-mass shakeouts create a high frequency impact force that is imparted into the casting with a minimum hp and energy requirements. Machine stroke is easily adjustable on two-mass shakeouts, which makes them adaptable to any shakeout situation. Two-mass shakeouts are ideal for high mold volume facilities.