Challenge

Oil City Iron Works, Inc. is a Texas based foundry specializing in gray iron casting, ductile iron casting, iron machining, ni-resist casting, and heat treatment. They currently have two molding lines, utilizing a BMM Molding Machine as well as a Hunter 20 molding line.

Prior to contacting GK, Oil City was utilizing a rotary media drum / shakeout from another manufacturer to process castings from both lines. Due to casting damage, they were extracting 60% of the castings from both the BMM molding machine and the Hunter line.

This caused many issues with the operation of the system:

- 60% of the castings were pulled from the process line, stored in totes, and needed to be cooled outside before being re-introduced to their process.

- The sand was left with high moisture and very little heat from iron, creating plugging issues in the drum and improperly prepared sand. This plugging required Oil City to install a gas heater at the entrance of the drum to create the needed BTU’s to prevent plugging.

- The Sand return system had large swings in moisture content, which upset the sand preparation system.

- An operator and fork truck was required full time for transportation of castings to and from the process line.

- The customer also did not have an auxiliary sand cooling system. This was a concern that whatever system was installed didn’t cause problems with elevated sand temperature.

Approach

Oil City engaged General Kinematics to create a shakeout solution that would be gentle, allowing all the castings to continue through the shakeout process without operator interaction. The castings would also need to be cooled, and fork truck operation would need to be limited. They wanted the sand and castings to be blended, cooling the castings while providing unified sand with consistent moisture content.

Solution

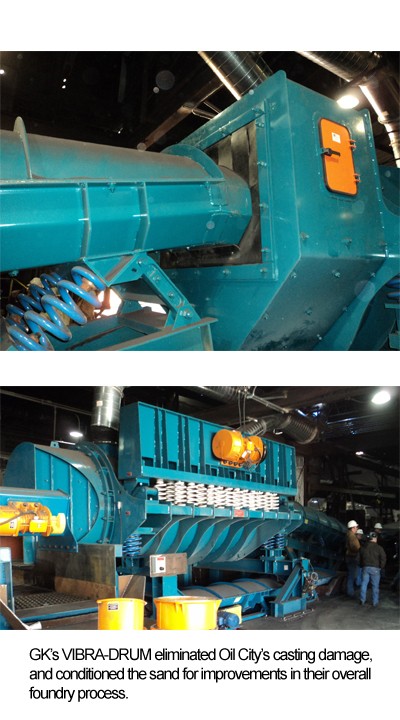

General Kinematics provided a Vibra Drum and vibratory shakeout installation within the existing footprint of the customer’s existing rotary shakeout equipment. The Vibra Drum takes the complete mold and gently tumbles the castings in the bed of sand, providing a lot of sand to casting interactions while preventing the castings from dropping on each other and getting damaged. In this rolling action the castings quickly lose heat, which is driven off into the cooler sand. Moisture from the molding sand is evaporated in this heat, allowing in the breakdown of residual sand lumps. This action conditions the sand back to loose grain sand, thoroughly mixed and homogeneous. To prevent high sand temperatures and prevent the sand from over drying (creating dead clays), a moisture addition system was also added to the Vibra Drum . This monitors the return sand temperature and modulates the amount of moisture added in the Vibra Drum accordingly.

Results

Oil City is extremely happy with their new GK solution. Their new system now can process 100% of their castings through the Vibra-Drum, eliminating outside cooling and the extra material handling that was required with the rotary media drum. The Vibra-Drum has also conditioned their sand, returning cooler sand with more consistent moisture to their sand system.