For Immediate Release

General Kinematics

Marketing Dept.: (815) 444-3594

marketing@generalkinematics.com

FOR IMMEDIATE RELEASE: BARRIER™A NEW WAY TO MONITOR

Introducing BARRIER™: Advanced Vibratory Equipment Monitoring

Have you experienced downtime? Even the smallest amount can be a financial drain. This year General Kinematics is ending the cycle of downtime with BARRIER™. The newest release from General Kinematics provides 3 levels of equipment tracking that can be customized to your process.

BARRIER™

VERTEX™

NOMADX™

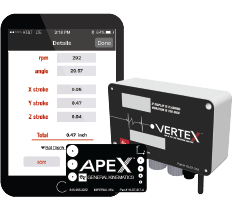

APEX™

This power-packed device can fit in your pocket to travel with your maintenance team and can be placed on any of your vibratory equipment to track vibrations and more. Open the app right on your smart device to sync APEX™ and view your equipment’s real-time data. Monitor vibration, stroke, frequency, and more at the click of a button.

Highlights:

- Plan your maintenance from actual data

- Parts replacement pre-failure is less expensive and will save money

- Send data easily to GK’s Field Service Team

VERTEX™

GK’s all-new VERTEX™ takes monitoring your vibratory equipment to a whole new level. Capable of monitoring your equipment 24/7, VERTEX™ transmits this data to your personal BARRIER™ Portal. The VERTEX™ will even send text alerts to your phone to let you know immediately if there is anything amiss. With advanced service options, GK will help you monitor and troubleshoot these alerts.

Highlights:

- BARRIER™ Basic now comes standard on all GK equipment

- Be alerted the moment an issue arises

- 24/7 equipment monitoring

NOMADX™

Our nomadic field service team will assist you with analyzing your data, monitoring your equipment, and implementing maintenance to keep your equipment running smoothly around the clock.

Highlights:

- Experienced professionals to analyze your data

- Solve Process or Production throughput issues

- Data Management

BARRIER™ offers

Convenience – Reliability – Experience

What’s your maintenance strategy? Are you looking for a better way to maintain your equipment? Don’t wait for downtime to happen. Utilize the data BARRIER™ provides to achieve excellence.

If you have a question about how GK’s BARRIER™ can better your process, call GK and talk to a member of the team today!

###

About General Kinematics

General Kinematics Corporation, incorporated in 1960, was established to market, design, and custom fabricate innovative vibratory materials handling and processing equipment. Today the company is one of the world’s largest suppliers of vibratory processing equipment, having held more than 200 worldwide patents, and is acknowledged as a major contributor to the technical advancement of vibrating equipment design and application. General Kinematics serves a worldwide customer base through a network of engineering-oriented independent sales representatives who cover major industrial markets throughout the United States. International markets are serviced from subsidiary operations and through a combination of representatives, licensed manufacturers, and strategic alliances with leading industry-specific organizations in other strategic locations. Today, over 50,000 General Kinematics units have been installed in virtually all of the world’s industrialized countries. As new process and efficiency challenges emerge, General Kinematics is uniquely qualified to address these needs with advanced technology, innovative engineering, new materials, and manufacturing techniques… all applied to improving customer productivity and profitability while meeting ever more stringent requirements. Today, GK knows no limit in our ability to provide a broad level of engineering support and capacity that other companies cannot offer. We bring a 360-degree view to the whole process picture, often supplying engineering resources our customers do not have, or do not wish to fund internally.