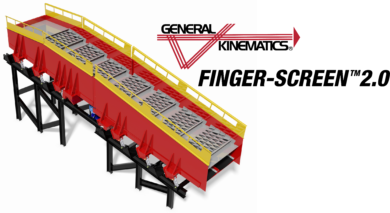

Trommels are known for causing trouble. Whether it’s Christmas lights, plastic film, or hoses something is bound to get wrapped around the rotating shaft screen and jam your machine creating a massive headache for you and a slowdown in productivity for your process not to mention the frustration of untangling. The General Kinematics FINGER-SCREEN 2.0™ uses the combination of finger decks and long strokes to keep material from wrapping and getting stuck in the machine.

Great for MSW, C&I and Single Stream applications, the superior performance of vibratory processing with GK’s unique FINGER-SCREEN™ deck delivers highly efficient separation and classification. Like the original FINGER-SCREEN™ Primary Screen that took the industry by storm, FINGER-SCREEN™ 2.0 features an enhanced vibratory action that spreads material across the deck for maximum utilization of the screen area. Tapered finger designs along with unique cam-out surfaces and staggered positions help to prevent material bypass. Separation performance is further improved as material freely cascades down the deck with less plugging, trapping, or pegging. The result: continuous, dynamic material flow to optimize separation and classification.

The FINGER-SCREEN™ 2.0 boasts more energy, faster travel rate, and a higher lift for challenging materials including garbage bags, yard waste, and other lightweight, flexible materials. Unlike Rotary trommels, which aerate materials, cause blinding and pass long pokers with a high level of daily cleaning and maintenance requirements, FINGER-SCREEN™ 2.0 separates materials based on 3D sizing with minimal blinding and minimal housekeeping. When used as the primary screen, FINGER-SCREEN™ 2.0 provides the initial size separation which scalps off any potentially destructive contaminants, allowing the rest of the downstream equipment to operate effectively.

Why trust a trommel when the FINGER-SCREEN™ 2.0 is tangle free?

Interested in relieving your trommel trouble? Call GK and ask about the FINGER-SCREEN™ 2.0 today!