Mining Advancements in Recent Years

The benefits of mining have increased greatly since the late 1900’s, due to multiple advancements in mining technology. Because of these advancements, the amount of coal and precious metals being procured from the earth have more than tripled in recent years. Strides in processing mean there is little need for harsh chemicals to derive desired material from its surrounding matter. New ways of extruding the desired material have provided greater return by increasing the purity of coal and precious metals giving the consumer greater heating value, stronger metals, and not to mention greater incentive to pay for this higher quality. At GK, we have harnessed the power of vibration to create the next generation of technological advancements in mining screens. With so many to choose from the question on your mind may be “what is the right fit for me?”. Below, we will walk through the important decision factors for which General Kinematics screen is best for your process.

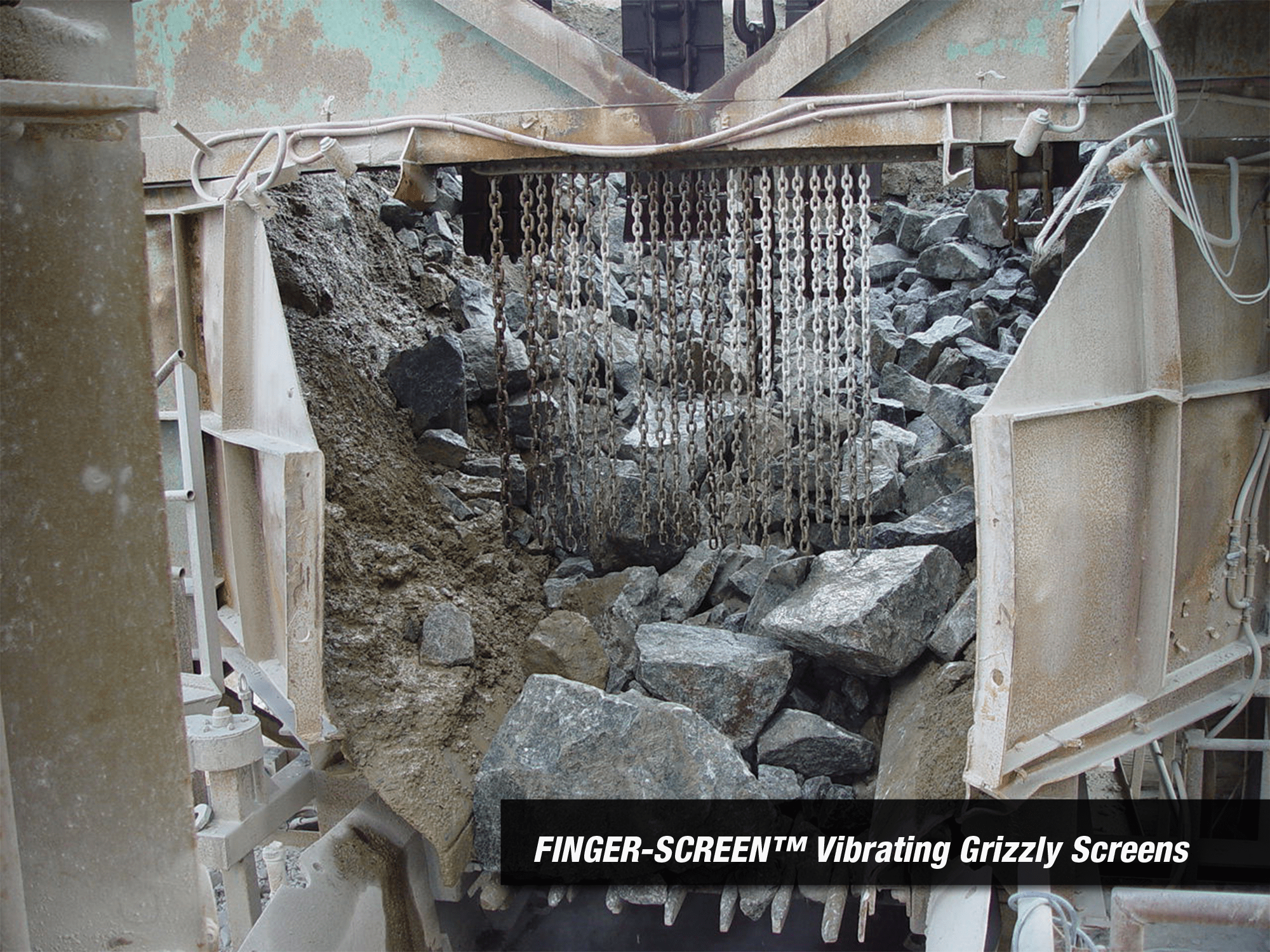

FINGER-SCREEN™ Vibrating Grizzly Screens

The FINGER-SCREEN™ Vibrating Grizzly Screen is built specifically for materials that are difficult to process. With improving your process in mind, the Vibrating Grizzly is built tough, fabricated from a heavy abrasion resistant plate and staggered finger positions engineered to prevent material bypass. The FINGER-SCREEN™ Vibrating Grizzly Screen classifies your challenging materials using vibratory motion and a tapered finger design. Built with the highest quality materials and designed to run 24/7/365, this screen is a tough one to beat.

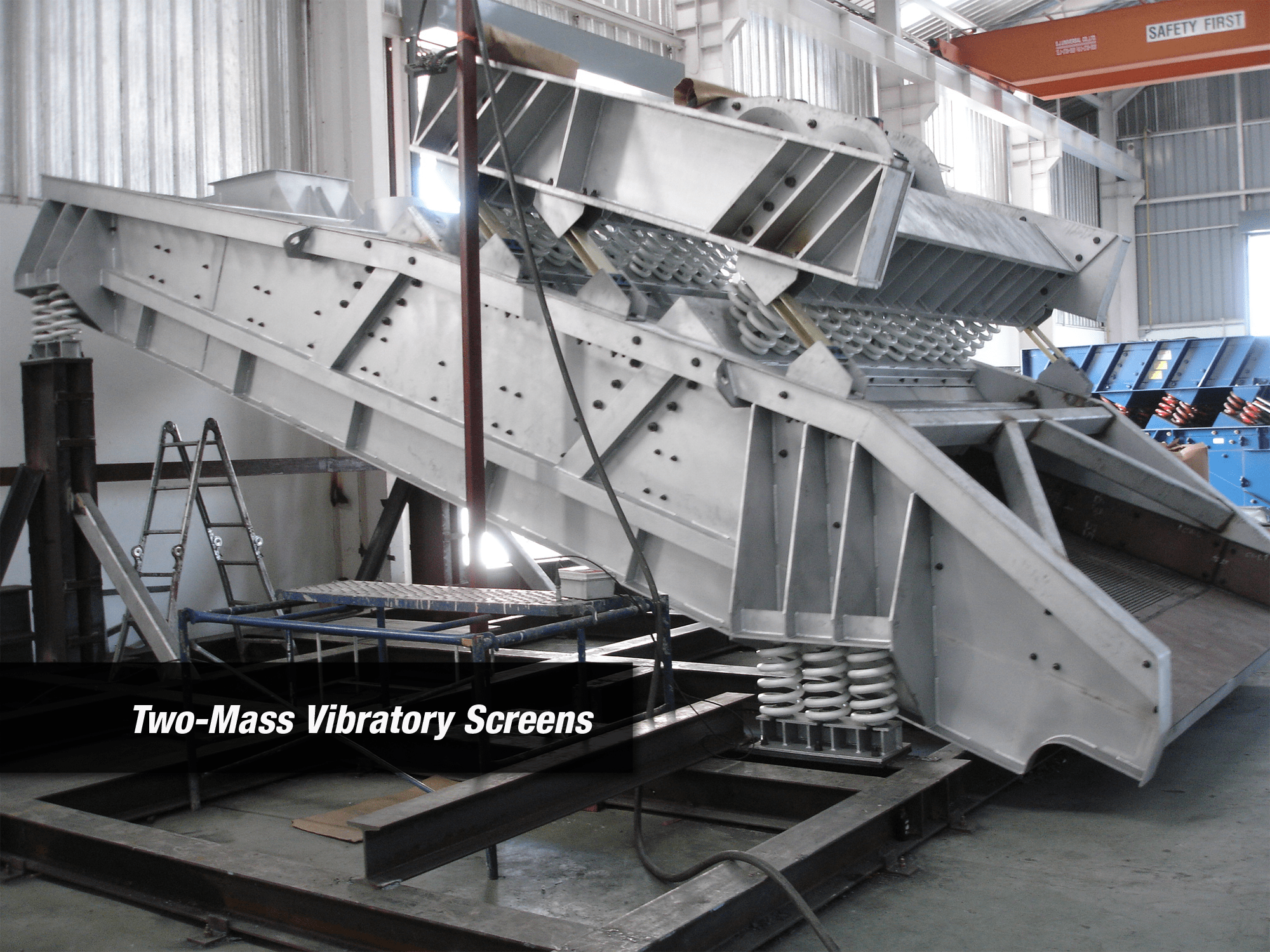

STM-SCREEN™ Two-Mass Vibratory Screens

General Kinematics STM-SCREEN™ Two-Mass Vibratory Screens are built to work your material more thoroughly. This screen is load responsive with longer retention times meaning the material discharges from the screen better separated. The screens’ Two-Mass design delivers higher performance and eliminates the need for expensive belts, shafts, bearings, and dual in-board vibratory motors. This Two-Mass Screen also has the lowest cost of ownership available in GK’s vibrating screen package. It offers maximum up-time with evenly spread energy and high structural integrity that is sure to prove its value. There are also customizable options to fit your specific needs.

Two-Mass Banana Screens

This screen is ideal for those looking to reduce your energy consumption while increasing the processing power of your line. The Two-Mass system requires up to two-thirds less horsepower than a brute force screen lending itself to being a much more energy efficient system. The Two-Mass Banana Screen does not have the maintenance issues associated with direct-drive designs. Best of all the Banana Screen is customizable with multiple decks, styles of screen surface, materials, and finishes, fitting into most applications and installation environments with ease.

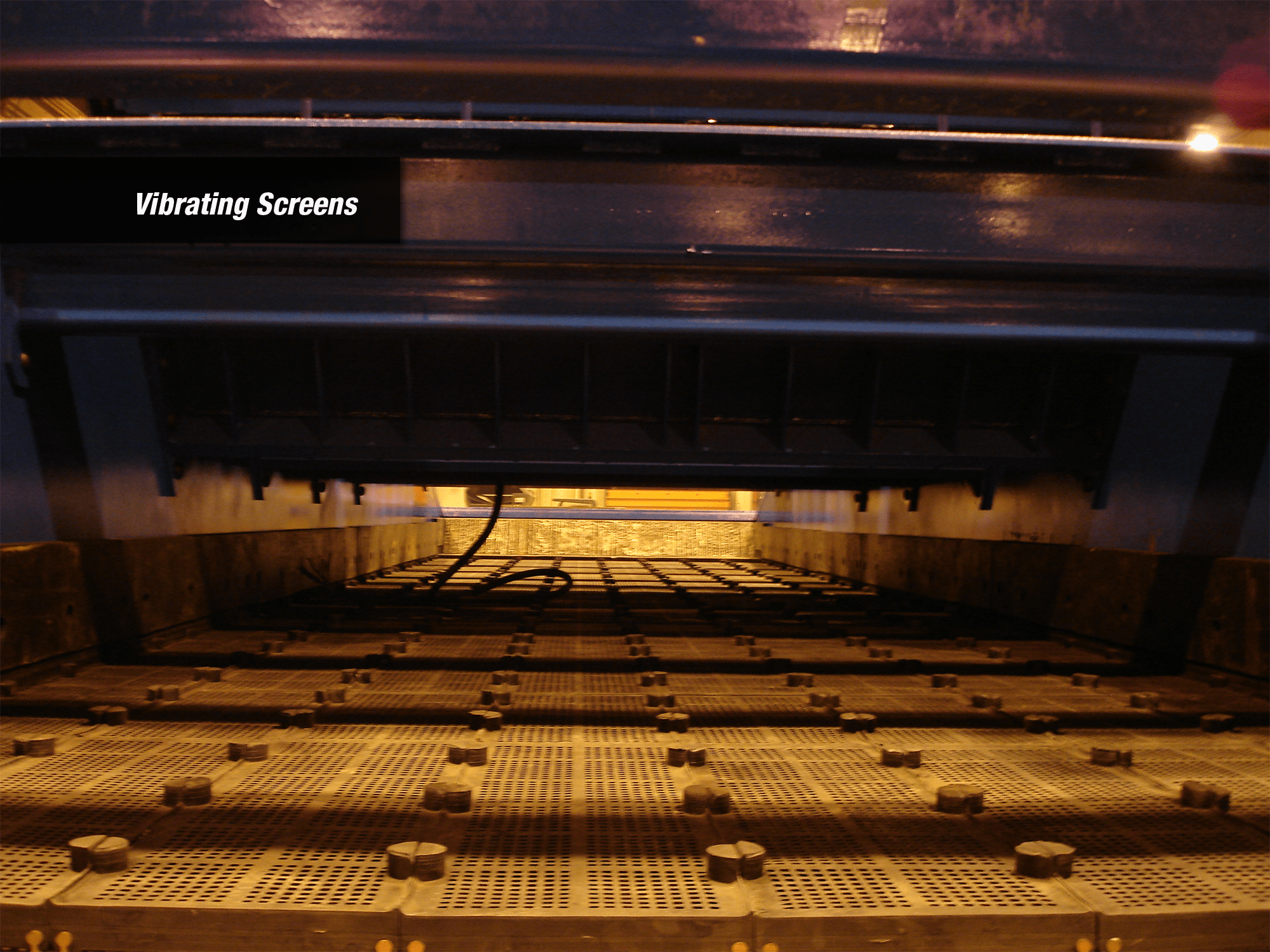

Vibrating Screens

This screen has options. If you are looking for a screen that will be flexible enough to fit your specific needs, the GK Vibrating Screen is the way to go. The ability to choose whether your screen is Two-Mass or Brute Force, type of screen, screen size, and Standard or custom size of the entire machine are just some of the benefits. This screen has an extra heavy-duty body to handle whatever you can throw at it. Not only is it tough, but cost effective with low maintenance costs. If you are looking for a flexible, reliable screen with great performance this is the one for you..

Two-Mass Vibratory Screens

The one word to sum up the Two-Mass Vibratory Screen? Efficient. But it is much more than just that. The Two-Mass Vibratory Screen is unequaled in performance with the proven Two-Mass drive system that maintains stroke even when the load is increased, in addition to electrical savings of up to 5 times. You cannot go wrong with this screen. It’s even customizable in the choice of deck, (corrosion resistant) finish, and overall size. The motors are mounted to the unit for fast change out, saving you precious time and money. The Two-Mass Vibratory Screen is built with you in mind, just plug it in, and it’s ready to take on the job.

GK Quality

Looking for a screen to fit your needs? At General Kinematics we custom-build our screens for you. With high performance and expert engineering, you are sure to find the best screen to fit your needs.

Due to advancements in mining technology that have equated to increased extraction rates, you want a screen that can handle bigger loads while increasing the purity of your desired material. Whether it be coal or precious metals, General Kinematics screens are proven to give the highest return. Have a question? Ask one of Our Experts!