Vibratory equipment includes a variety of machinery that use vibrations for bulk material processing, including those specifically designed with the recycling and scrap material industries in mind. In most cases, vibratory equipment uses less energy, requires less maintenance, is more reliable, and increases output.

The Vibratory Machinery Industry

Over time, vibratory machinery and equipment have become more widely used and more specialized for industrial purposes. Easily explained by the principles of economics, i.e. supply and demand, the development and improvement of these machines were primarily driven by the industry urgency and need.

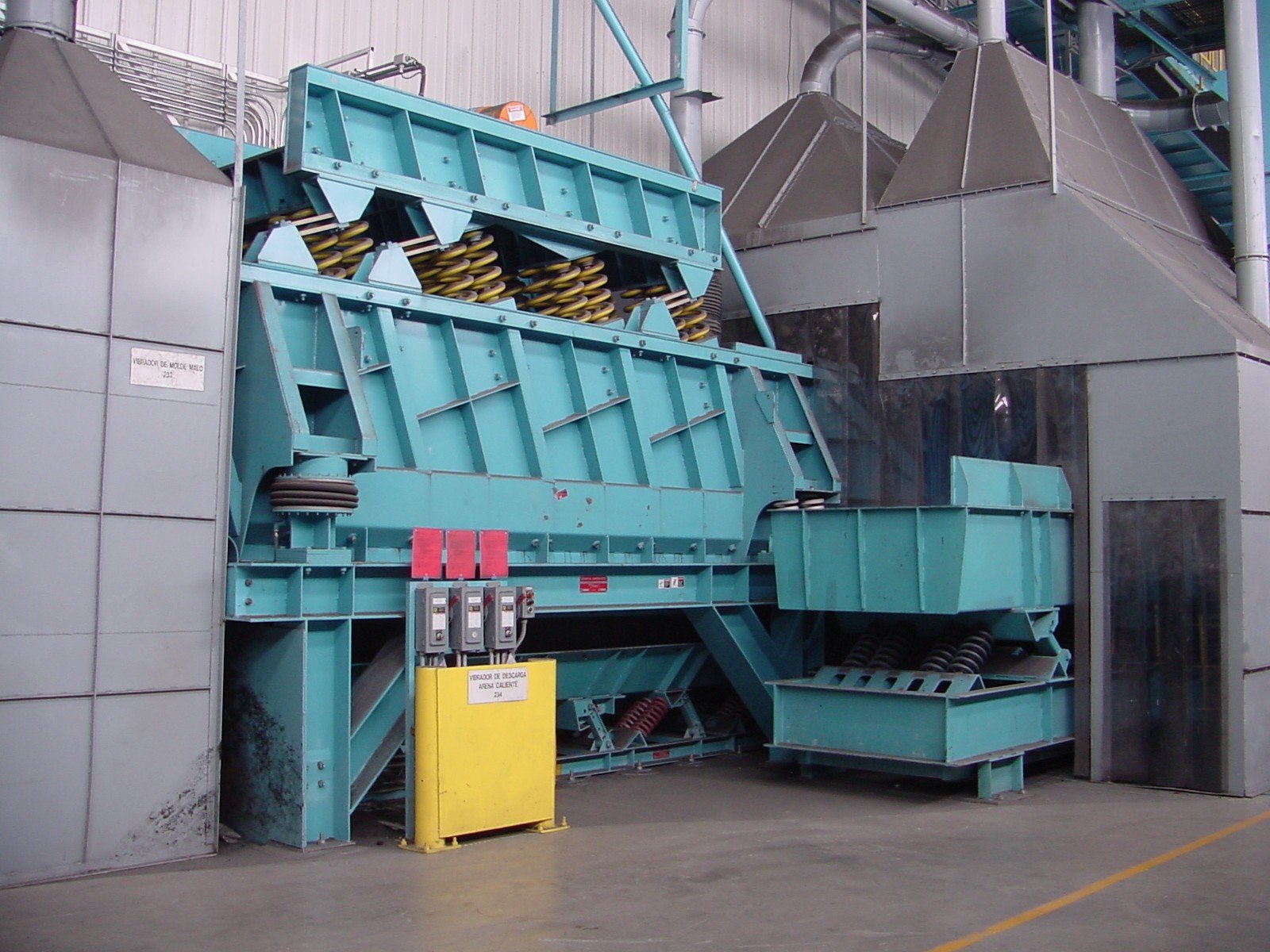

Foundation in Metal Casting

In the 1960’s General Kinematics Founder, Al Musschoot discovered an overwhelming need for custom vibratory equipment within the metalcasting industry. Being well versed in vibratory sciences and experience working with one of the largest standard vibratory equipment suppliers of the time, he started his own business offering solutions to foundries that were not available elsewhere.

GK’s VIBRA-MILL® Sand Reclaimer, SPIRA-COOL® Casting Cooling Conveyor, and VIBRA-DRUM® Sand and Casting Conditioner would soon become well-known names in foundries across the US and eventually the world. The need for custom solutions has only grown since Al opened the door to General Kinematics back in 1960. Expansions in industry products and new methods of casting have made heavy-duty vibratory machinery more important now than ever. Not long after General Kinematics was founded, it became apparent that vibratory equipment was in growing demand across industries.

Today General Kinematics develops vibratory solutions for over 16 key industries and has more than 50 thousand installations worldwide. The demand for vibratory machinery continues to grow with new applications and discoveries improving mission-critical processes around the world on a daily basis.

Resource Recovery

At General Kinematics, we offer a wide variety of energy-efficient vibratory machinery and equipment for purposes related to recycling scrap materials. One product, the DE-STONER® Air Classifier, couples vibration with high-velocity, low-pressure air streams to fluidize commingled materials for the time-efficient separation of light materials (e.g., paper, aluminum, wood) from heavy materials (e.g., stones, metals, glass) based on terminal particle velocity.

Additionally, our patented FINGER-SCREEN® Primary Screen design avoids many of the issues commonly associated with conventional wire mesh screening, such as jamming. With the FINGER-SCREEN®, vibration spreads the materials evenly along the surface of the machine, and staggered fingers help prevent material bypass to achieve better separation than rotary trommels and disk-type screening equipment.

Mining and aggregate

The mining and aggregate industry is always evolving, looking for new ways to extract the most valued minerals from their site. General Kinematics’ STM SCREEN™ Two-Mass Vibratory Screen has been making waves among leaders and innovators in the mining industry. Providing improved classification for increasing load densities, the STM-SCREEN™ is the able to handle these modern mining demands.

GK has also made great strides in grinding processes, grinding abrasive materials to recover precious minerals with the VIBRA-DRUM™ Grinding Mill. This unit achieves a 93-97% recovery rate without the use of toxic chemicals such as arsenic, relieving the environmental burden of the remaining chemical aggregate mixture and the disposal process which it entails. Many of GK’s mining and aggregate units, such as the PARA-MOUNT II® Vibratory Crusher Feeder offer lower energy consumption along with the benefits of durability and load responsiveness.

General Kinematics innovates to create the most efficient and dependable processing equipment to ensure the timely and consistent handling of your bulk materials. Our equipment can heat, cool, coat, convey, feed, elevate, agglomerate, and grind all kinds of materials according to the needs of the process.

In addition to our equipment, we offer a wide variety of services, including vibratory analysis and troubleshooting to help improve processes and resolve issues related to both GK and non-GK vibratory equipment. Contact our experts at General Kinematics to find out how our machines can improve your processes.