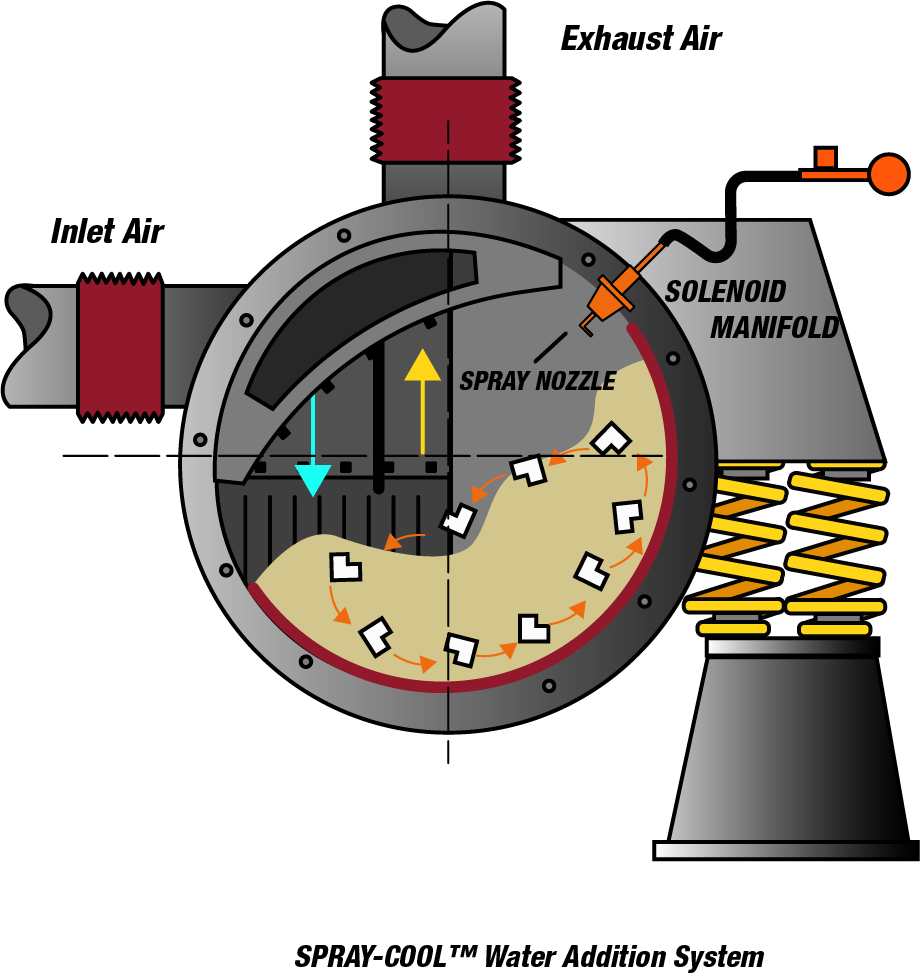

Proven in hundreds of applications worldwide, VIBRA-DRUM® Sand & Casting Conditioners have revolutionized high volume mold/sand handling for foundry applications. The VIBRA-DRUM®, in combination with GK’s SPRAY-COOL™ Water Addition System, creates the right environment for accelerated casting and sand cooling through free evaporation. By evaporating moisture, much more heat energy is released than through traditional direct conduction cooling in sand.

To control the amount of moisture being added, General Kinematics uses data from the foundries’ molding lines to calculate the proper moisture levels. This data includes:

- Molding Rate and mold size

- TPH of Iron Poured

- Signal for unpoured or cool molds

A secondary monitoring of discharge temperatures helps ensure the system is operating correctly.

A common foundry problem when working with molds is driving too much moisture out of the clay. Dead clay is generated in the mold where the molten iron meets the green sand. This can also be generated when too much moisture is driven out of the sand during the Shakeout process. Think of dead clay as baking flour in a bowl. If you try to add water to the flour, it just runs off. It takes time for the clay (bentonite) to absorb that moisture. Moisture levels are therefore monitored closely. By discharging sand out of the VIBRA-DRUM® and sending this moist sand back to storage, the unit helps the sand system by re-activating the dead clays, giving the clay time to absorb the moisture blended in the sand.

During punchout, casting temperatures entering a VIBRA-DRUM® are typically between 1000-1200°F. General Kinematics designs the Drum accordingly to avoid any potential casting quenching when mixed with sand. Because there is a high amount of energy and moisture being released from the sand, the exhaust air system is designed to accommodate for a heavy burden of moisture. In addition, enough heated or fresh air is added to the inlet air stream to prevent condensation. These calculations vary dependent on elevation, ambient temperature, and humidity and are determined by engineering in advance.

Lastly, SPRAY-COOL™ Water Addition Systems are carefully engineered into the VIBRA-DRUM® in several zones with differing nozzle volumes to spread the moisture evenly. This allows time for the moisture to blend thoroughly into the sand and to have time to evaporate and cool the castings.

Interested in learning more about implementing General Kinematics’ VIBRA-DRUM® Sand & Casting Conditioners into your process? Contact me to learn more.