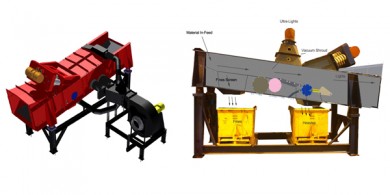

DE-STONER® vibratory/air classification technology presents high velocity, energy-saving air streams operating at low pressure so that separating and fluidizing of compounded materials is completed through detection of the velocity of particles within the air streams. Additionally, DE-STONER® systems are equipped with devices called “air curtains” that facilitate classification of materials following removal of heavier particles. This means that weightier materials like metals, glass and stones are cleanly detached from lighter items such as paper, wood and plastics.

Benefits and Features of the DE-STONER® Vibratory Air Classification System

- Needs no water supply

- Handles all conditions of materials, including moist or soggy items

- Eliminates environmental dangers frequently associated with recycling machinery that use water energy and therefore requires “dumping” of contaminated water.

- Nearly maintenance-free design is attributed to immobile separator components and minimal requirements regarding foundation demands.

- Powered by an energy-efficient motor that operates efficiently on low amounts of horsepower.

- DE-STONER®’s versatility allows for classification of materials composed of equal or varying densities containing different particle sizes.

- Durable and rugged, DE-STONER® can withstand round-the-clock operation to maximize company efficiency and provide high ROIs to business owners.

Originally used in the agriculture industry to separate chaff from wheat, air classifiers have replaced inefficient, traditional separators by utilizing advanced technology recycling devices such as the DE-STONER® to facilitate differentiating of commingled materials without increases in overhead expenditures. In addition, DE-STONER® offers air recirculation technology that improves performance of its classifier by capturing air emitted by the machine and recirculating it through the DE-STONER® device. Because dust and debris emissions are dramatically reduced facilities remain safer and cleaner for everyone involved in the recycling process. In addition, upgrading any DE-STONER® air classifier with an air recirculator is not only easy but affordable as well. For more information, contact General Kinematics today.