Last year proved to be a record year for many in the recycling industry. Though the news of restrictions being placed on China’s imports caused alarm for the whole of 2017, many had yet to see the economic effects of this new ruling until the fourth quarter.

Unfortunately, it is expected to become more prevalent throughout 2018 with an increase in limitations to 0.5 percent taking place on March 1st. Taking notice of the pain point created by lack of income from exports, regional scrap buyers have taken notice and driven prices down even further in the national setting. In preparation for the negative effects of this increase in regulations and falling prices, many major players in the recycling industry have made plans for the upcoming year to adverse the effect.

The list of action items spans from increasing material sorting power to reorganizing financial structures. The most effective of which will most likely be to increase material purity to reopen the door to China.

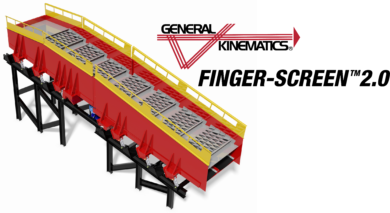

Over the next year many leaders in the recycling industry are investing in material sorting and robotics. The recent advances in robotic sorting have made it possible to sort more in a shorter amount of time. Now when you add this increased sorting efficiency to a system employing primary and secondary sorting screens like the GK FINGER-SCREEN™, the result becomes something unseen in previous years.

The initial screening process removes fines and small objects that can get in the way of optical sorting installations as well as providing them with a more evenly-spread pile of materials to sort through. Along with advances in robotics, many companies are working with equipment manufacturers such as General Kinematics to create the next generation of sorting equipment. One outcome of this end to end collaboration is the FINGER-SCREEN™ 2.0 which has already begun to prove its processing power in the field. Improving upon proven designs will create next level sorting systems capable of maintaining the lowest contamination rates we have yet to see.

It is important to have a plan as early as possible to minimize the effects of the China ban. Putting a plan in place now can make a major difference for the 2018 financial year.

If you are looking to innovate your line or implement the latest in vibratory sorting technology from General Kinematics, give us a call. With over half a century of sorting experience, GK has what it takes to make your facility state of the art.