A unique secondary aluminum producer, located in Kentucky, had recently purchased a more efficient rotary furnace to improve their foundry production. Optimum efficiency requires the furnace doors to be opened and closed in the shortest amount of time to maintain heating efficiency. To feed the new furnace, the current process involved multiple runs using a front end loader to weigh material and charge the furnace to capacity, leaving the doors open for an extended amount of time. The resulting loss of heat makes the process less efficient. With the loader having to travel 90 feet to the furnace, and then lifting up 48 inches to charge the furnace, the end user needed to find a better solution to charging their furnace.

Approach

The end user came to General Kinematics looking for a unique solution to resolve their process issue. They knew that General Kinematics has had numerous proven and successful furnace charge system for the foundry industry. These systems range from stationary charge systems, indexing charge systems, indexing and traversing charge systems, wireless remote controlled charge car systems as well as a pivot lift charge system. Backed by theses proven examples and successful installations, the end customer felt very comfortable working with General Kinematics.

Solution

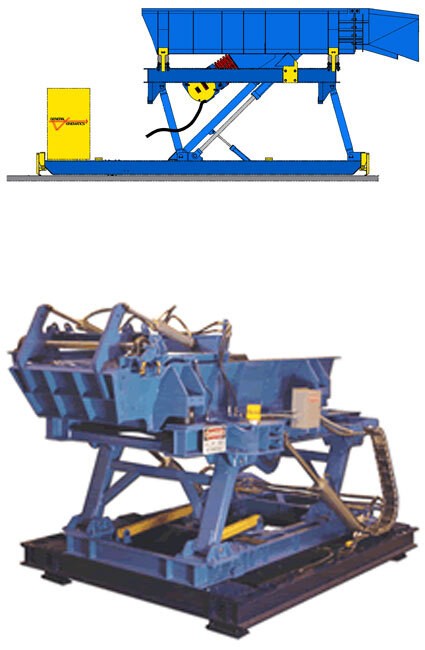

General Kinematics designed a unique solution consisting of a wireless controlled, four bar lift, indexing charge feeder travelling on embedded rails. The four bar lift assembly provided a low feed height for the front end loader in addition to a raised height to charge the furnace with 15,000 lbs of materials. Charging time was now reduced to less than 1 minute. This unique solution permits the isle to be open for traffic access as the embedded rails would be out of the way while all electrical power will come from an overhead festoon system. The operation is overseen remotely from an operator located in the control tower 90 feet from the furnace. The operator controls the entire process from indexing, lifting, charging, and return from the one location in the control tower.

Results

By working with the customer and understanding their challenges, GKC was able to provide a unique solution which will reduce heating cost, reduce material handling issues, increase productivity, and save money for the end user.