Traditional grinding mills reclaim only a fraction of precious metals from ore, leaving valuable material in the tailings. These minerals are more difficult to liberate, as it requires the ore to be ground to a very fine mesh.

Approach

GK was approached by a company who had a proprietary chemistry solution for recovering minerals from an existing mine tailing pile. Through development work, GK created a new mechano-chemical process incorporated throughout the mining & minerals industry to transform low market grade material into engineered high grade material.

Solution

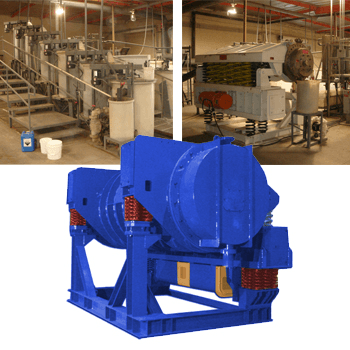

General Kinematics mechano-chemical technology produced a higher percent of precision product output utilizing adaptive technology based on GK’s VIBRA-DRUM® solutions. The system includes GK’s VIBRA-DRUM® grinding mill, leach stations, filter press, resin columns and dewatering units, mixing tanks, and related systems and controls.

Results

GK’s Solutions Group enhanced the outcomes of the existing mechano chemical process to alter and engineer material to achieve unmatched precision output at the desired specifications. Recoveries of 93 – 97% were achieved without the use of toxic chemicals such as cyanide due to the unique fracturing in the ore. Payback results are proprietary to customer’s new market plans.